Is Bakken oil safe enough for the Greater Toronto Area? by Jessica McDiarmid, December 14, 2013, Toronto Star

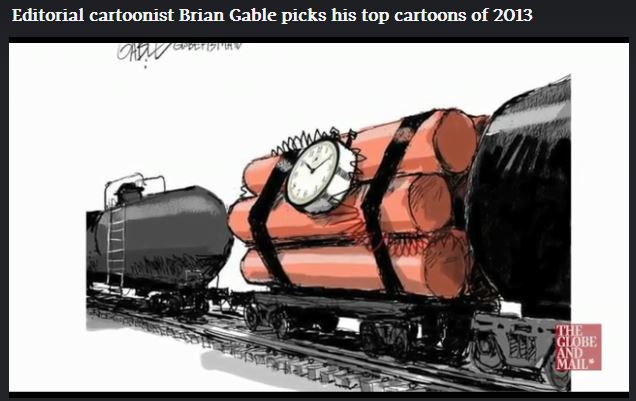

The Lac-Mégantic disaster raises concerns about fracked crude from North Dakota and Saskatchewan. … A train carrying 72 cars of crude oil had barreled into the sleepy Quebec town of Lac-Mégantic and derailed. And the oil did what crude oil isn’t supposed to do: it blew up, killing 47 people, leaving the downtown core in ruin.

Photo: Mathieu Belanger, Reuters. Charred tanker cars lie in the ruined town of Lac Megantic on July 9, after a derailment and explosion that surprised oil safety experts with its ferocity. The oil being carried, from the Bakken formation, was far more volatile than its documentation suggested.

The crude oil on that train came from North Dakota, where it was pulled from the shale of the Bakken formation, which stretches from western North Dakota into southern Saskatchewan and eastern Montana. It’s the same oil Enbridge plans to pump through Line 9, a pipeline that cuts through the GTA if federal regulators approve plans to reverse the flow in the 38-year-old pipeline to supply Quebec refineries with cheaper products from western Canada and the Bakken region.

The composition — and flammability — of crude oil varies, depending on where it’s extracted. The oil that exploded in Lac-Mégantic was mislabelled in shipping documents as less dangerous than it really was.

Now, railway regulators in Canada and the U.S. are homing in on Bakken oil and potential safety concerns when it is shipped by rail. There are worries it may be more corrosive and more explosive than oil extracted elsewhere.

Line 9 would also carry diluted bitumen — heavy, tar-like crude from Alberta’s oil sands, diluted with chemicals so it can flow through a pipe — though the majority of product would be light crude from the Bakken, according to Enbridge.

Industry reports have noted the corrosive effects of Bakken oil on drilling and refinery infrastructure, but there are no special rules for its handling, nor have its effects on pipelines been probed by federal regulators on either side of the border. “Regulators don’t treat crude oil from the Bakken any different than they treat crude oil from the tar sands or from Oklahoma,” said Carl Weimer, executive director of the Washington-based Pipeline Safety Trust. “No one’s ever really looked at whether different types affect pipelines different. “It seems like it should be a concern, we just really haven’t heard about it that much.”

In the days that followed the blasts in Lac-Mégantic, as police officers and firefighters pulled bodies from the mangled wreckage, safety investigators said the crude oil — not generally seen as a highly flammable product — had acted in an “abnormal” way. “Most people were quite surprised by the strength of the fire and the subsequent explosions,” said lead investigator Don Ross. Months later, Ross’s investigation would find the flammability of the oil — misclassified in documents — was closer to that of gasoline than typical crude.

Most of the oil produced in North Dakota is extracted using hydraulic fracturing, or “fracking,” a controversial process of blasting apart underground rock formations with a high-pressure mix of water, sand and chemicals to get at oil and gas trapped within. Producers use a toxic soup of chemicals, such as hydrochloric acid, a highly corrosive component that critics fear could eat away at pipelines and tank cars if not fully removed from the oil.

And Bakken crude can contain high levels of hydrogen sulfide, a toxic, corrosive chemical that’s extremely flammable. Earlier this year, Enbridge got into a spat with shippers when it asked federal regulators for permission to reject crude oil with hydrogen sulfide levels higher than 5 parts-per-million — after tests revealed a batch of crude bound for a pipeline at its Berthold, N.D., facility had levels of 1,200 ppm. Human exposure to hydrogen sulfide at 50 ppm or higher can cause death. The batch Enbridge successfully rejected contained 24 times the lethal level.

But it was Enbridge that pushed for that 5 ppm limit, which was protested by oil producers. No regulations require it. Some companies don’t have such limits.

Enbridge spokesperson Graham White said the company samples batches of crude that goes through its lines. Oil with high levels of contaminants, such as hydrogen sulfide, are flagged and dealt with, to protect both people and pipeline.

…

Rhona Delfrari, a spokesperson for Alberta-based oil producer Cenovus Energy, said the composition of its oil from the Bakken in southern Saskatchewan isn’t very different from other sources. “It’s not drastically more explosive by any means, not even close,” said Delfrari. “Oil is pretty much oil.”

Chemical engineer Gregory Patience, who studies explosions in petroleum and fossil fuels, looked up a safety data sheet published by Cenovus on its Bakken product. [Available at link below]

The oil’s flammability classification is the highest there is, level 4 — the same as methane gas and propane…. “Is it more dangerous, is there a hazard? Yes, there’s a hazard; yes, there’s a risk,” said Patience. … [Emphasis added]

[Refer also to:

http://www.cenovus.com/contractor/docs/CenovusMSDS_BakkenOil.pdf

Safety alert issued over dangers of fracked oil, Lac-Mégantic voted top Canadian news story of 2013

MUST WATCH: Catastrophe Lac Mégantic by Adrien Aubert [616,083 views as of January 6, 2014]