Assessment and risk analysis of casing and cement impairment in oil and gas wells in Pennsylvania, 2000–2012 by Anthony R. Ingraffeaa, Martin T. Wellsc, Renee L. Santorob, and Seth B. C. Shonkoffd june 30, 2014, Edited by William H. Schlesinger, Cary Institute of Ecosystem Studies, Millbrook, NY, approved May 30, 2014 (received for review December 17, 2013),doi: 10.1073/pnas.1323422111 Proceedings of the National Academy of Sciences of the United States of America

Unconventional gas wells in northeastern (NE) Pennsylvania are at a 2.7-fold higher risk relative to the conventional wells in the same area.

To whom correspondence should be addressed. E-mail: email hidden; JavaScript is required

Or have the frac skeletons kicked the closet doors off?

Fracking industry fumes as researchers reveal high levels of leaking methane by Lucy Nicholson, Reuters, July 01, 2014, rt.com

The latest drilling techniques for obtaining gas, which drill horizontally as opposed to the more traditional vertical drilling, shows a higher rate of leaking methane, according to a study that could spell problems for fracking across the nation. After poring over data from the Pennsylvania Department of Environmental Protection involving more than 41,000 wells, it was determined that more than 6 percent of the active gas wells drilled in the Marcellus region of Pennsylvania “show compromised cement and/or casing integrity,” according to an academic paper published on Monday by the Proceedings of the National Academy of Sciences. A team of four scientists – working without federal funding – conducted analysis on more than 75,000 state inspections of gas wells performed in Pennsylvania since 2000.

The results suggest that hazardous leaks of methane could pose potential obstacles for drilling across the nation, said study lead author Cornell University engineering professor Anthony Ingraffea, who leads an environmental activist group that helped subsidize the study. The leak rate of methane was found in nearly 10 percent of horizontally drilled wells for before and after 2009 in the northeastern part of Pennsylvania, where fracking is a serious business. “Something is coming out of it that shouldn’t, in a place that it shouldn’t,” said Anthony Ingraffea, Cornell professor of civil and environmental engineering who led the research team, as quoted by AP.

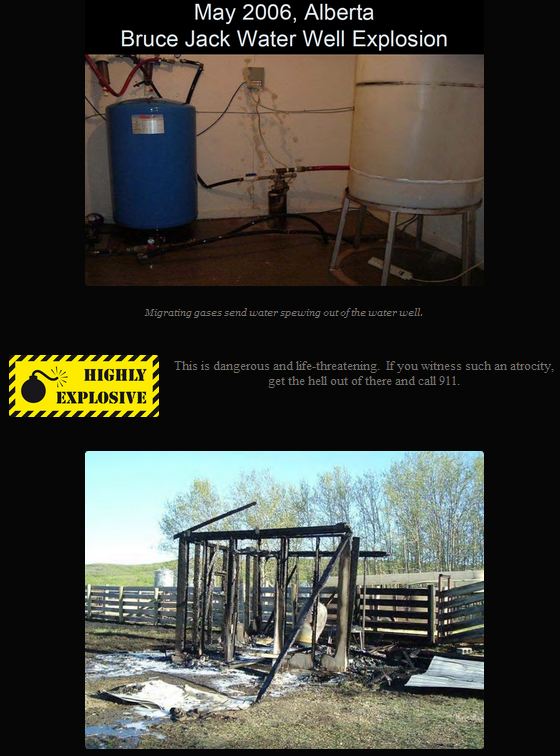

The researchers admitted they are not sure exactly where the leaking methane goes — into the water or the air, but neither alternative is a positive prospect in light of a number of incidences thought to involve the escaping gas. “These results, particularly in light of numerous contamination complaints and explosions nationally in areas with high concentrations of unconventional oil and gas development and the increased awareness of the role of methane in … climate change, should be cause for concern,” said the researchers in the paper.

Bruce Jack and two industry gas-in-drinking water testers were seriously injured and hospitalized by industry contaminating Jack’s water with methane and ethane

The researchers did not specify the size of the leaks, saying only that the metal pipes used to extract the natural gas were suffering “casing and cement impairment.”

“In a typical well, hundreds of bags of cement are mixed and injected,” said Ingraffea. “If the water-to-cement mixture ratio isn’t right, you have problems. With too much water, the cement shrinks. With too little water, the mixture dries too fast.”

…

Other contributors to the paper, ‘Assessment and Risk Analysis of Casing and Cement Impairment in Oil and Gas Wells in Pennsylvania, 2000-2012’, were Martin Wells, Cornell professor of statistical sciences; Renee Santoro of Physicians, Scientists and Engineers for Healthy Energy, Ithaca, New York; and Seth Shonkoff, University of California, Berkeley. [Emphasis added]

New concerns arise over fracking’s safety by Bruce Kennedy, July 2, 2014, CBS News

The ongoing controversy over the method for removing oil and gas from unconventional, hard-to-reach underground deposits that’s known as hydraulic fracturing, or “fracking,” has some new data to chew on. It seems a large percentage of oil and gas wells tapping the Marcellus Shale region of Pennsylvania are leaking methane gas, either into the air or into underground sources of drinking water.

That’s the finding of an analysis conducted by a Cornell University-led research team and published this week in the Proceedings of the National Academy of Sciences. The team looked at compliance reports for more than 41,000 conventional and unconventional oil and gas wells in Pennsylvania. It determined that unconventional gas wells in northeastern Pennsylvania had a nearly three-fold higher risk of leaking, compared to conventional wells in the same region.

One possible factor for this so-called “methane migration,” according to the study, could be “compromised structural integrity” in the casings and cement used in the unconventional oil and gas wells.

“These results, particularly in light of numerous contamination complaints and explosions nationally in areas with high concentrations of unconventional oil and gas development and the increased awareness of the role of methane in anthropogenic [man-made] climate change, should be cause for concern,” it concluded.

…

The energy industry has fired back against the new report. “This paper is a work of deception that massively exaggerates the risks of domestic oil and natural gas production,” Katie Brown, spokesperson for Energy in Depth — a program of the Independent Petroleum Association of America (IPAA) — said in a statement.

…

However, opponents have been pointing to fracking’s potential health dangers, such as possible wide-scale pollution of essential drinking water supplies, as reasons to limit or even completely ban the process. But Mark Zoback, a Stanford University geophysicist, member of the National Academy of Engineering’s Deepwater Horizon investigation committee and a fracking expert, says this technology has a place, as long as the states and federal government set up rigorous standards to oversee its use and protect both the public and the environment. [But, instead, across North America, regulators are fast deregulating while publicly saying they’re doing the opposite]

“The oil and gas industry is a large-scale industrial process, [like] food preparation, aviation, transportation, chemical plants,” Zoback recently told the Los Angeles Times. “We live in a highly technological and complex society,” he said, “and the only way we can survive is through the marriage between technology and regulation.” [Emphasis added]

Fracking Study Finds New Gas Wells Leak More by Seth Borenstein, Associated Press, June 30, 2014, ABC News

In Pennsylvania’s gas drilling boom, newer and unconventional wells leak far more often than older and traditional ones, according to a study of state inspection reports for 41,000 wells. The results suggest that leaks of methane could be a problem for drilling across the nation, said study lead author Cornell University engineering professor Anthony Ingraffea, who heads an environmental activist group that helped pay for the study.

The research was criticized by the energy industry. Marcellus Shale Coalition spokesman Travis Windle said it reflects Ingraffea’s “clear pattern of playing fast and loose with the facts.”

…

The study was published Monday by the Proceedings of the National Academy of Sciences. A team of four scientists analyzed more than 75,000 state inspections of gas wells done in Pennsylvania since 2000. Overall, older wells — those drilled before 2009 — had a leak rate of about 1 percent. … Newer traditional wells drilled after 2009 had a leak rate of about 2 percent; the rate for unconventional wells was about 6 percent, the study found.

The leak rate reached as high as nearly 10 percent horizontally drilled wells for before and after 2009 in the northeastern part of the state, where drilling is hot and heavy.

The researchers don’t know where the leaky methane goes — into the water or the air, where it could be a problem worsening man-made global warming. The scientists don’t know the size of the leaks or even their causes and industry officials deny that they are actual leaks. The study calls it “casing and cement impairment,” but the study’s lead author says that is when methane is flowing outside the pipe.

“Something is coming out of it that shouldn’t, in a place that it shouldn’t,” said Ingraffea, who has been part of a team of Cornell researchers finding problems with fracking. Also, Ingraffea heads a group of scientists and engineers that has criticized fracking and two of his co-authors are part of the group. The study didn’t discuss why the leak rate spiked. Ingraffea said it could be because corners are being cut as drilling booms, better inspections or the way the gas is trapped in the rock formation.

Pennsylvania regulatory officials said their records show that gas leaks peaked in 2010 and are on the way down again, reflecting their efforts to stress proper cementing practices. Further in 2011, the state focused more on unconventional wells to make leak protection efforts “more stringent,” wrote Morgan Wagner, a spokesman for the state environmental agency.

Energy industry officials attacked the study and Ingraffea. Chris Tucker, spokesman for industry-supported group Energy In Depth, said what they measured may not be leaks but state inspectors detecting pressure buildup. “The trick these researchers are pulling here is conflating pressure with leakage, trying to convince folks that the mere existence of the former is evidence of the latter,” Tucker wrote in an email.

But outside scientists, even pro-drilling ones, praised the study. Terry Engelder of Pennsylvania State University, a pioneering supporter of the Marcellus fracking boom, said it shows there is plenty of room for improving drilling safety. “It clearly indicates that there is a problem with the production” of the wells, said University of California Santa Barbara engineering professor and methane expert Ira Leifer, who wasn’t part of the study. [Emphasis added]

Study Digs Deep on Shale Gas Wells, Methane Leaks by Bobby Magill, June 30th, 2014, Climate Central

Ingraffea’s analysis found that newer oil and gas wells — those that use modern hydraulic fracturing and directional or horizontal drilling techniques to tap shale gas deposits…are more likely to leak methane than older wells drilled using less advanced technology.

Over a 100-year timeframe, methane is a greenhouse gas that is about 34 times as potent as climate change-driving carbon dioxide, and over 20 years, it’s 86 times as potent.

Methane leaks come from defects in the cement and steel linings of oil and gas well bores that protrude into the earth sometimes thousands of feet. Both groundwater contamination and methane leakage into the atmosphere are the result, according to the study. The amount and rate of methane leakage is unknown, Ingraffea said.

…

Well cementings and casings have a long track record of being imperfect, and sometimes lead to underground leaks. Pennsylvania state inspectors’ records show that the steel or cement well casings were compromised in up to 9.1 percent of the active oil and gas wells in the state that were drilled since 2000, with a higher risk coming from the newer wells drilled since 2009.

Failure rates of the casings or cementings tend to be higher in northeastern Pennsylvania than other parts of the state, but it’s unclear why, he said. There is less gas underground in western Pennsylvania than in the eastern part of the state, possibly contributing to a lower well casing failure rate in the west than in the east, he said.

Ingraffea said Monday that the cement used to encase a well bore to prevent fluid and gases from leaking into underground aquifers sometimes fail for many reasons. “Some of them are installation problems,” he said. “Some of them are material problems. Long-term performance problems.” The cement could have been installed improperly or allowed to set too quickly, he said, or too much water could have been used to mix the concrete. The reports used in the analysis are state public records filed by environmental inspectors who visit individual oil and gas well sites and detect methane leaking from the wells and into the atmosphere, he said. Ingraffea said he has no data on the rate that the methane is leaking from individual wells.

…

“Hydraulically fractured shale wells appear to have more problems than conventional wells,” Jackson said. “If so, it’s probably because the wells are longer, must bend to go horizontal and take more water and pressure than in the past. The combination makes well integrity a challenge.

“We can’t tell how much methane is leaking to the air based this study. That will require more work.” [Emphasis added]

[Refer also to:

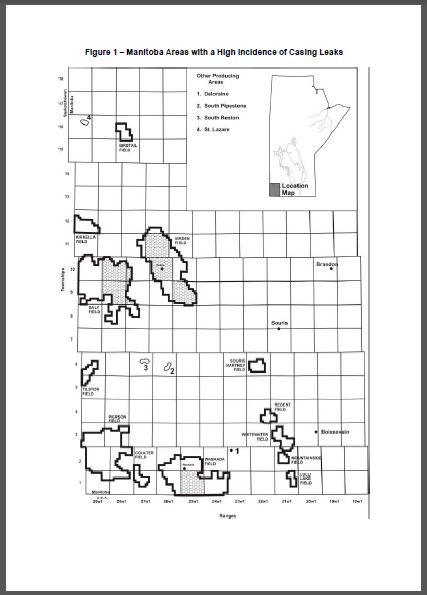

Map from 2004 Informational Notice 04 – 02, Wells with casing leaks Manitoba Industry, Economic Development and Mines

Map from 2004 Informational Notice 04 – 02, Wells with casing leaks Manitoba Industry, Economic Development and Mines

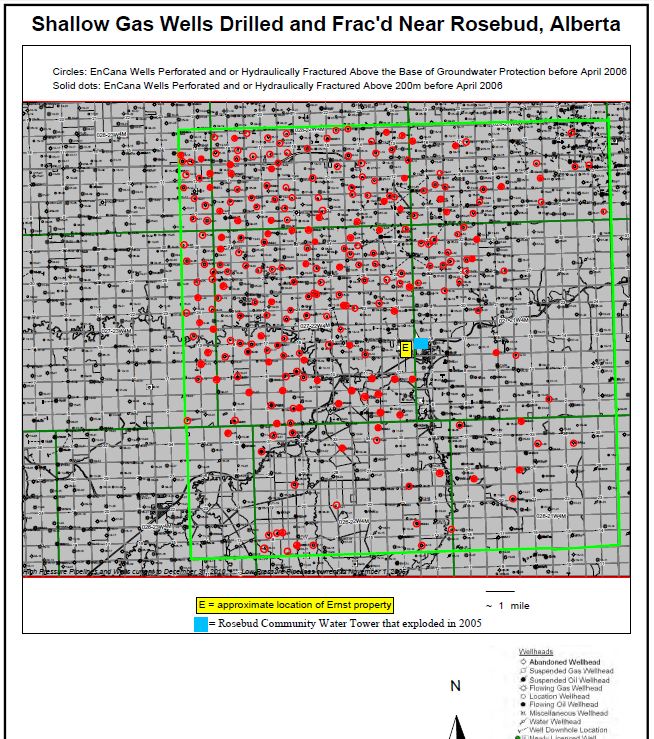

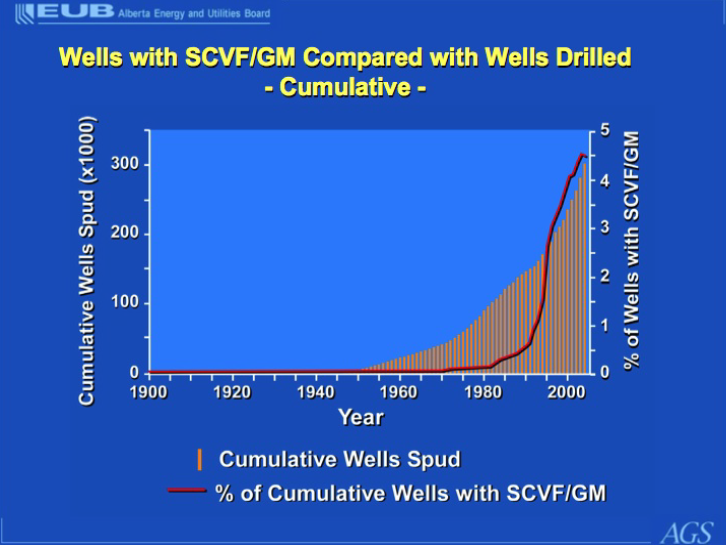

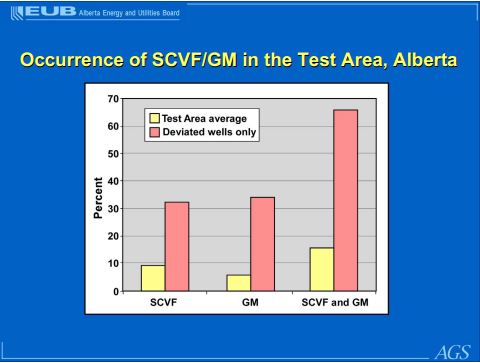

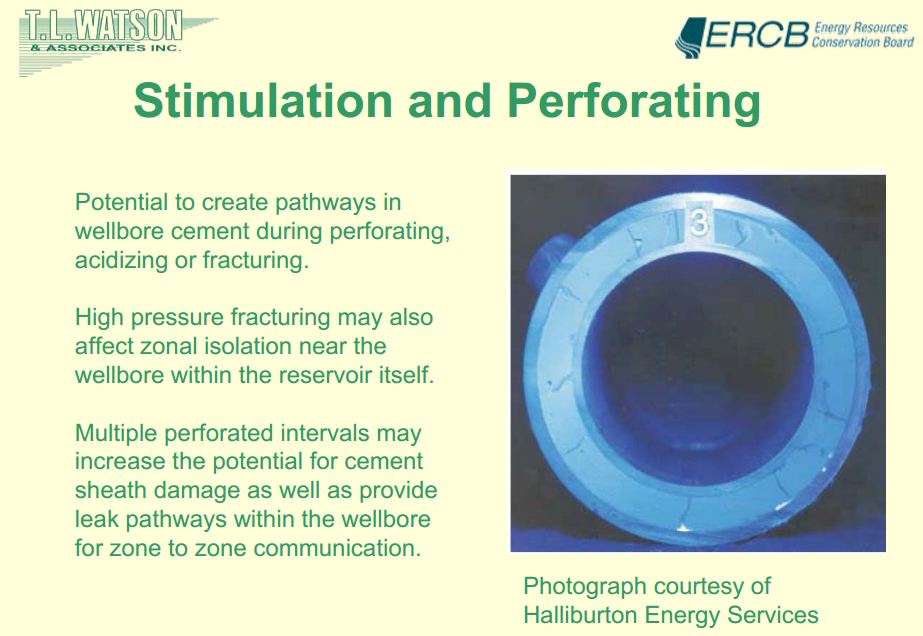

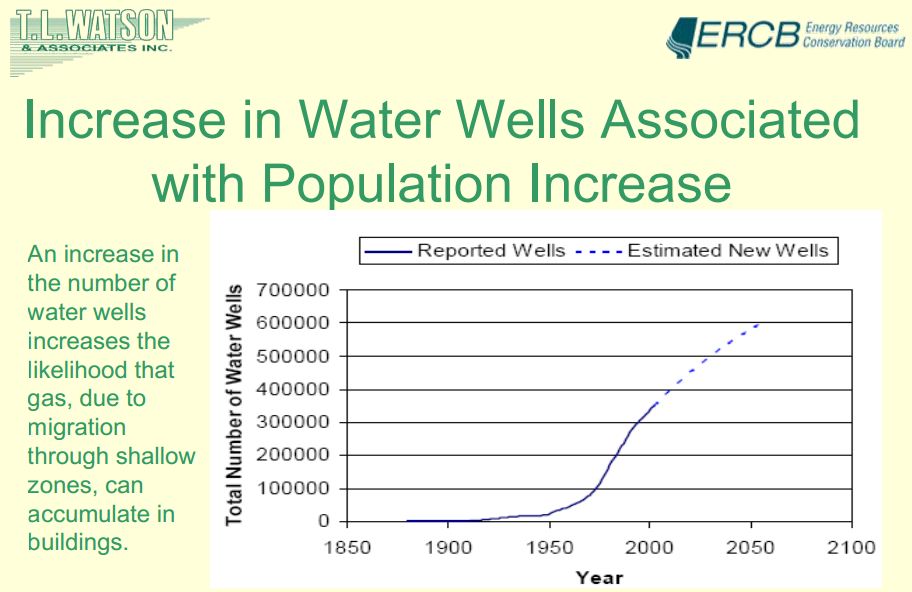

Slides from Factors Affecting or Indicating Potential Wellbore Leakage by Dr. Stefan Bachu (Alberta Energy and Utilities Board, now AER) and Theresa Watson (T.L. Watson and Associates Inc.), 2007. SCVF = Surface Casing Vent Flow; GM = Gas Migration

Slides from presentation at Fourth Wellbore Integrity Meeting in Paris, France on March 19, 2008 by Theresa Watson (T.L. Watson & Associates) and Dr. Stefan Bachu (ERCB)

Source: Hutchinson Gas Explosion – Unraveling a Geologic Mystery by Kansas Geological Survey, University of Kansas