Philly refinery blast released 5,000 pounds of deadly chemical, federal investigators say, Aging, thin pipe likely cause of fire by Andrew Maykuth, The Philadelphia Inquirer, Oct 16, 2019, in Pittsburgh Post-Gazette

Philadelphia dodged several potential catastrophes during a dramatic June 21 refinery blast, which released about 5,239 pounds of deadly chemical and launched pieces of shrapnel as large as a truck hurtling across the 1,300-acre refinery complex, according to a federal findings released Wednesday.

The disaster at Philadelphia Energy Solutions complex began with the early morning failure of an elbow section of pipe that had corroded to half the thickness of a credit card, according to investigators for the U.S. Chemical Safety and Hazard Investigation Board (CSB). In a matter of minutes, the fire triggered three successive explosions, the largest of which blew a fuel tank into massive projectiles, including one weighing 19 tons that traveled 2,100 feet and landed on the opposite bank of the Schuylkill.

The failure of a section of pipe was similar to a 2012 accident at a Chevron refinery in Richmond, Calif., after which the CSB recommended that refinery operators inspect all components of the piping systems. That was not done at PES, said Kristen Kulinowski, the CSB’s interim executive.

The agency’s report is the first to confirm the release of toxic hydrofluoric acid, a material used as a catalyst in the alkylation unit that was destroyed in the blast.

“The board remains concerned that the next time there is a major explosion at a refinery that uses HF for alkylation, workers and those living nearby will not be so lucky,” Kulinowski said. “By their nature, refineries are high hazard operations and it is imperative that they are run and managed with the most robust of safety management systems.”

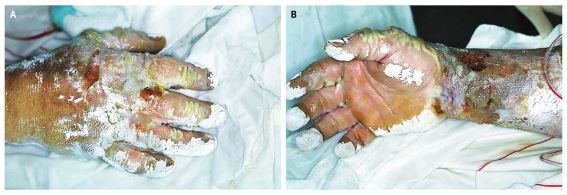

The acid can destroy tissue and bone, and has caused fatalities with skin exposures to as little as 2.5% of body surface area, the CSB said. “If inhaled, HF can cause severe lung injury and pulmonary edema – fluid in the lungs – which can result in death,” the report said.

Despite the release of hydrofluoric acid, and a fireball that flung large chunks of steel through a complex where millions of barrels of crude oil and fuel were stored, there were no deaths. Only five refinery workers experienced minor injuries that required first aid treatment, CSB said.

“The CSB is unaware of any offsite or onsite health impacts from the hydrofluoric acid release,” the agency said.

The Chemical Safety Board has investigated about a dozen refinery incidents in the last 20 years, including those resulting in fatalities, serious injury, and property damage. The agency has no enforcement powers and can only make recommendations. [That will be ignored, yet again] Other agencies, including the Occupational Safety and Health Administration, are also investigating

The CSB’s 10-page “factual update” does not attempt to affix blame or fully explain the circumstances leading to the fire, which shut down the largest oil refinery on the East Coast. Company officials said the explosions caused severe damage to the 150-year-old site, which had been processing 335,000 barrels of crude oil daily into gasoline, jet fuel, propane, home heating oil and other products.

The report does not suggest whether the refinery’s longstanding financial problems or its maintenance practices contributed to the accident.

The refining company and its workforce appear to be the biggest casualty of the accident. Its owners announced the plant’s closure on June 26, throwing most of the 1,100 workers out of jobs, and filed for Chapter 11 bankruptcy protection in July. The refinery remains shut down as the U.S. Bankruptcy Court in Delaware determines if its creditors will take ownership, or the complex will be sold.

PES estimated that about 676,000 pounds of hydrocarbons — mostly propane, butane and butylene used in the alkylation processing unit — were released during the event, of which 608,000 pounds were combusted or burned up.

Thirty seconds after the fire started, a control-room operator emptied most of the hydrofluoric acid in the alkylation unit into a “rapid deinventory drum,” a system the refinery’s previous owner, Sunoco Inc., had installed more than 10 years ago to reduce the chances of a catastrophic release of HF in such an accident.

But a “low concentration” of HF remained in some of the equipment that failed during the event, and PES estimated that 5,239 pounds was released. About 1,968 pounds of the released hydrofluoric acid was contained by water spray within the unit and was processed in the refinery wastewater treatment plant. But about 3,271 pounds was released to the atmosphere. In a gaseous state, HF is called hydrogen fluoride.

At the time of the fire, a shelter-in-place order was put in place for residents near the refinery, but no evacuation ordered. The Philadelphia Health Department measured an “elevated” level of hydrogen fluoride gas outside the South Philadelphia refinery during a fiery the accident, but the reading was dismissed as a “false positive.”

The disaster unfolded in a matter of minutes. CSB said the alkylation unit was operating normally, and then at 4:00:16 a.m., a sudden loss of containment in the piping system in the unit caused a combustible mixture of process fluid and hydrofluoric acid to release, forming a “ground-hugging vapor cloud.”

Less than two minutes later, the cloud ignited. About 30 seconds later, the control room operator emptied the hydrofluoric acid from the unit into the safety storage drum.

At 4:15 a.m., 13 minutes after the fire began, the first explosion occurred, followed by a second at 4:19 a.m. At 4:22, the third explosion occurred when a large drum containing butylene, isobutane and butane ruptured.

That explosion, captured by remote television cameras, sent three large fragments of the drum flying in different directions. A 38,000-pound piece traveled four-tenths of a mile and landed on opposite bank of the Schuylkill, near the refinery’s tank farm. Two other pieces, one weighing 23,000 pounds and another weighing 15,500 pounds, landed in the refinery.

The reason for the pipe failure remains a metallurgical mystery. One of the CSB’s remaining challenges appears to be trying to resolve why one elbow section of pipe in the doomed alkylation unit failed while others that had been inspected recently showed no sign of excessive corrosion.

The piping circuit in the PES alkylation unit that contained the ruptured elbow was installed in about 1973, and CSB said it appears to be original piping. The pipes are subject to regular ultrasonic thickness measurements at designated “condition monitoring locations” as part of a PES inspection program to monitor metal losses due to corrosion.

A pipe wall thinner than 0.18 inch is subject to replacement. But the most recent measurements did not indicate a thin pipe — PES recorded wall thicknesses ranging from .229 to .345 inch in previous tests.

The elbow joint that failed, however, was among several that were not subject to the measurements. CSB measured the pipe after the incident and said that at its thinnest point, it measured a mere 0.012 inch thick, or 7% of the minimum, or about half the thickness of a credit card.

The ruptured steel pipe elbow contained a much higher percentage of nickel and copper alloys than the adjacent joint, which measured well above the standard thickness. CSB noted that industry experts had singled out nickel, copper and chromium alloys as contributing to a higher corrosion rate in pipes that contain hydrofluoric acid.

CSB said the failure was reminiscent of a 2009 refinery explosion in Woods Cross, Utah, and a 2012 accident at the Chevron Richmond Refinery near San Francisco, both of which involved pipes that had corroded and burst.

Refer also to:

Philadelphia: Authorities proclaim air safe to breath up and down wind of Energy Solutions Inc’s massive refinery blasts and fire, even after explosions in “highly toxic chemical” hydrofluric acid akylation unit, metal debris landed a mile away and air testing not yet complete

HYDROFLUORIC ACID, Hydrogen Fluoride, 7664-39-3. Health Hazard Information by the EPA, created April 1992, updated January 2000:

Acute Effects:

Acute inhalation exposure to gaseous hydrogen fluoride can cause severe respiratory damage in humans, including severe irritation and pulmonary edema. Irritation of the eyes, nose, and upper and lower respiratory tract, lacrimation, sore throat, cough, chest tightness, and wheezing have been reported.

Severe ocular irritation and dermal burns may occur following eye or skin exposure in humans.

Convulsions and cardiac arrhythmias and death from cardiac or respiratory failure may occur in humans from ingestion of high doses of fluorides.

Damage to the lungs, liver, and kidneys has been observed in animals acutely exposed to hydrogen fluoride by inhalation.

Acute animal tests in rats, mice, guinea pigs, and monkeys have demonstrated hydrogen fluoride to have moderate to high acute toxicity from inhalation exposure.

Snap from New England Journal of Medicine: Hydrofluoric acid burn

Hydrofluoric Acid: What You Need to Know: Hydrofluoric acid has unique properties that make it extremely dangerous to emergency personnel and others

Failure Investigation Report: Failure of Piping at EnCana Swan Wellsite A5-7-77-14 L W6M by the BC Oil and Gas Commission, February 4, 2010.

The 22 November 2009 failure…was caused by internal erosion of the wall resulting from flowing fracture sand suspended in the gas stream. Leak detection and emergency isolation at the site did not achieve timely detection of the leak or control of the escaping gas. EnCana’s integrity management program did not effectively mitigate the hazard of internal erosion.

EnCana Corporation facing criminal charges

$250000 in community safety projects following Encana deadly sour gas leak