Typical, CanWhite Sands out of Calgary changed its name to Sio Silica Corp.

To befuddle the many citizens opposed?

2022 10 18: Municipal Board delves into RM, sand company zoning dispute

In early May of 2021, CanWhite Sands extracted a large quantity of silica sand from a quarry site south west of Vivian Manitoba. Under the dry windy conditions at the time, silica dust was observed blowing in the direction of houses nearby. A complaint was filed with Manitoba Occupational Safety. Shorty after the sand piles were covered. However drillers, quarry workers, and likely nearby public were exposed to silica dust during the extraction operations.

It is happening again. On Aug.18, 2021, a large pile of freshly extracted sand was observed uncovered at the same quarry site. Nearby residents reported deafening noise from the drilling and extraction operations. CanWhite repeatedly disregards the health and safety of workers and the public in their silica sand extraction operations.

… “Sharp dealings” is a legal term used to describe sneaky maneuvers that are technically legal but border on the unethical.

There are several examples of this in the case of the proposed CWS silica sand mining project.

The most flagrant of these is the way in which both the provincial and federal governments set out initially to limit the scope of the review of the proposed CWS development project under the Manitoba Environment Act and the federal Impact Assessment Act, respectively. …

… The subsequent WDNR surface water lab report (Lab 113133790, dated 8/12/2019) indicated that EPA designated contaminants such as Arsenic, Aluminum, Chromium, Lead, Mercury, and others were scores to over 2,000 times the maximum contamination limits. …

Is the Manitoba sand coated with marcasite as in Wisconsin? It was laid down under the same conditions in the Ordovician era.The marcasite oxidizes when exposed to air and water to form acid that mobilizes heavy metals.

2021 06 08: A dry comment in from a Manitoban to this page:

We encourage community minded entrepreneurs from Alberta to transform our sand aquifers into acid and heavy metal filled caverns. They use the sand to frack your aquifers. They teach our children to be entrepreneurs and how to play scrabble.

2021 05 23: Hair-raising letter by retired judge Tom Lister to Roberta Walls, DNR, Wisconsin frac sand “regulator”

2021 05 13: CanWhite Sands (copying propaganda by Synergy Alberta/CAPP/Insider Education et al?) gave money to Springfield Chamber of Commerce to support “young entrepreneurs of Springfield” and an ad campaign promoting it:

2021 05 13: After a visit from Work Place Safety and Health following May 10 complaint CanWhite’s sand piles were covered (way too late for those exposed). See how close the home is in the background:

From: [name removed to protect complainant]

Date: Mon, May 10, 2021 at 5:38 PM

Subject: Re: FW: Complaint regarding potential occupational exposure to silica dust from the extraction of silica sand May 2021 at the LSL quarry south of Vivian MB

To: +WPG112 – Wshcompl (FIN) email hidden; JavaScript is required

2021 05 10: Public health hazard complaint regarding Canwhite uncovered silica sand piles which exposed workers and neighbouring families since May 5, 2021.

Thank-you

On Mon, May 10, 2021 at 1:18 PM +WPG112 – Wshcompl (FIN) email hidden; JavaScript is required wrote:

Good Day,

The information has been assigned to the Hygiene Team.

Client Services

Department of Finance

Labour Programs - Workplace Safety & Health

200-401 York Ave

Winnipeg, MB R3C 0P8

Ph: 204.957.7233

Toll Free: 1.855.957.7233 Press 1

FAX: 204.948.2209

Email: email hidden; JavaScript is required

Internet: manitoba.ca/labour/safety

Call 204-957-SAFE (7233) press 1 in Winnipeg or toll-free 1-855-957-SAFE press 1 anywhere in Manitoba to report unsafe work. You can also email email hidden; JavaScript is required or report online.

From:[name removed to protect complainant]

Sent: 2021-May-Mon 12:56 PM

To: +WPG112 - Wshcompl (FIN) <email hidden; JavaScript is required>

Subject: Complaint regarding potential occupational exposure to silica dust from the extraction of silica sand May 2021 at the LSL quarry south of Vivian MB

Dear Workplace Safety and Health

I am reporting a potential occupational exposure to PM10 and PM2.5 silica dust at the LSL quarry south of Vivian Manitoba near the junction of the Hydro line and highway 302. The attached satellite images show newly extracted piles of silicas sand at the quarry on May 5, 2021. No sand was visible on April 27, 2021.

That the extracted sand contains PM2.5 and PM10 respirable silica has been confirmed by proponent responses to questions from Eastern Manitoba Health recorded in CanWhite Sands Vivian Sand Processing Facility Project Registry 6057.00 The relevant proponent response to a question from the Interlake Eatern Health has been copied below.

"Interlake Eastern Regional Health Authority - July 28, 2020. Please provide data on the levels of respirable silica (less than 10 micrometer diameter) in the raw material and in the reject piles.

Proponent response:

Two samples of raw sand slurry material were analysed by a third-party laboratory. Results showed 0.67% and 0.45% of particulates less than 11 micometers in size which would represent particles that include clay, silica or a combination of both. It is expected that that only a fraction of these fine particulates (if any) will be silica, and all fines, including and silica, will be removed from the sand within a closed environment in the Processing Facility during the wet process. These fines will be bound within the Filter Cake that is produced during the dewatering process, as described in detail below." https://www.gov.mb.ca/sd/eal/registries/6057canwhite/tab1_responses_to_tac_vivian_sand_facility_eap_review_2020-10-08.pdf

The sand is extracted wet from the sandstone aquifer about 200 feet below ground by air-lift wells. The sands piles have dried out under current drought conditions. The quarry workers are likely being exposed to respirable silica dust from the sand piles that are out on the open and uncovered.

An abandoned pit nearby is used as a shooting range. Youth and the public use nearby trails for recreational vehicles and walking. Houses on highway 302 are about 700 meters away. The public may be exposed to the silica dust as well as quarry workers. Attached are satellite photos from sentinel-hub.com showing the silica sand piles in the quarry.

Please take the necessary action to ensure workers and the public are not exposed to respirable silica dust.

Thank-you

[name removed to protect complainant]2020 06 11: Steinbachonline reported Brent Bullen COO of CanWhite Sands claimed that his stockpiles of silica sand, derived by mining directly from the Sandstone aquifer, pose roughly the same threat as the sand along Grand Beach.

NIOSH warnings: https://www.cdc.gov/niosh/docs/92-107/default.html

WARNING! Exposure to crystalline silica during rock drilling can cause serious or fatal respiratory disease.

The National Institute for Occupational Safety and Health (NIOSH) requests assistance in preventing silicosis and deaths in workers exposed to respirable crystalline silica. The need is urgent to inform surface coal mine and other rock drillers, driller helpers, employers of drillers, and drill rig manufacturers about the respiratory hazards associated with drilling operations. Your assistance in this effort will help prevent silicosis-related death and disease, a national goal for health promotion and disease prevention stated in Healthy People 2000 [DHHS 1990].

This Alert describes 23 cases of silicosis from exposure to crystalline silica during rock drilling. Of the 23 workers reported, 2 workers have already died from the disease, and the remaining 21 may die eventually from silicosis or its complications.

NIOSH requests that editors of trade journals, safety and health officials, labor unions, and employers bring the recommendations in this Alert to the attention of all workers who are at risk. NIOSH also requests that manufacturers of drill rigs and other rock drilling equipment become familiar with and implement the source control measures recommended in this Alert.

Background

Case No. 2–Acute and Accelerated Silicosis

In April 1979, a 34-year-old male rotary driller reported a 6-month history of shortness of breath, dry cough, weight loss, and pale skin color in body extremities [Banks et al. 1983]. For the preceding 5 years, this worker had operated a rotary drill at a surface coal mine using dry drilling methods. Examination revealed increased heart and breathing rates, abnormal lung sounds, healed ulcers on the fingertips, reduced lung function, and abnormal chest X-rays. Open lung biopsy confirmed acute silicosis. Although the patient was treated with aggressive therapy for 8 months, lung function continued to deteriorate and the patient died of respiratory failure in June 1981.

Discovery of this case of acute silicosis led to a medical survey of nine other drillers who worked for the same company. Two of the workers, aged 28 and 31, had accelerated silicosis and had been drillers for fewer than 6 years. Exposure concentrations are unknown because the crystalline silica content was not measured in the coal dust samples collected during the years 1972-80. However, much of the rock encountered by the drillers was sandstone, which is likely to have had a high crystalline silica content.

2021 05 10: Dennis LeNeveu responds to Director Nicole Armstrong, Manitoba Water Branch

2021 04 28: New reports and letter added below [Emphasis added to parts included below]

Overview from D.M LeNeveu’s Feb 2021 report:

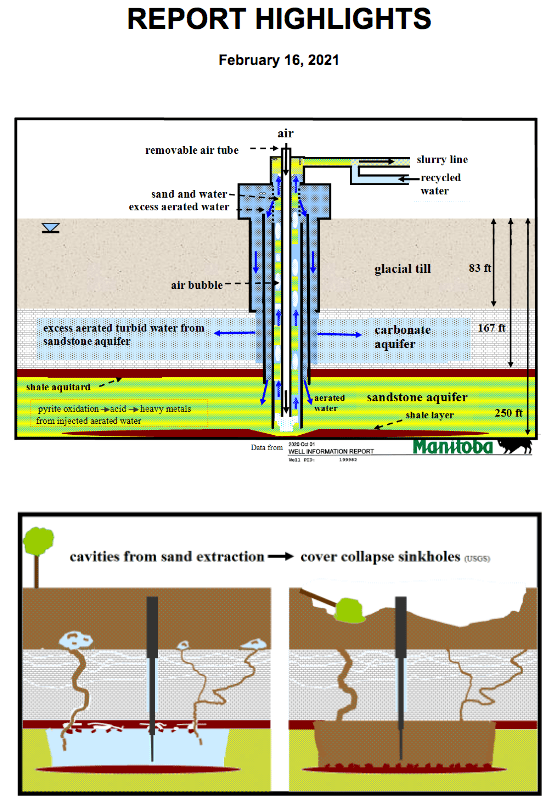

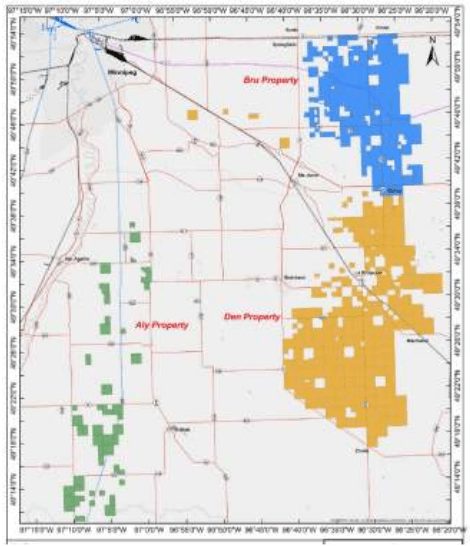

HD Minerals/CanWhite Sands Inc. (CWS) plans to extract silica sand from the Winnipeg Formation aquifer that together with the overlying carbonate aquifer supplies water to a large portion of south east Manitoba. The sand is to be extracted using air lift wells that would withdraw a mixture of air, sand and water from the sandstone aquifer of the Winnipeg Formation. Excess aerated water is to be returned to the formation. The sand is to be delivered to the CWS Vivian Sand Processing Plant by means of closed loop slurry lines. The sand is to be stockpiled and processed at the plant at Vivian, Manitoba, township SE32-10-8E. Silt and fine sand are to be removed in a clarifier tank at the processing pant and the water returned to the remote extraction locations to pick up more sand. A large number of extraction wells will be drilled to deliver 1.36 million tonnes of silica sand per year to the processing plant. After up to five days of extraction each well is to be sealed. The lifetime of the project is expected to be 24 years. CWS has over 80,000 hectares of mineral claims for sand extraction as shown in Figure 1. Not included in Figure 1 is the potential CWS extraction of silica sand from existing or future quarry leases over a larger area.

****

2021 04 26: Comparison of Hanson Lake Silica Sand Project to the Vivian Silica Sand Project by D.M. LeNeveu, B. Sc. (hons. physics), M.Sc. (biophysics), B. Ed., April 26, 2020, On Behalf of What the Frack Manitoba

How does the Hanson Lake Silica Sand Project in Saskatchewan compare to Vivian Silica Sand Project in Manitoba? What can we learn from a comparison? The Environmental Impact Statement for Hanson Lake silica mine published Oct. 29, 2019 was developed with guidance from the Saskatchewan Environmental Assessment and Stewardship Branch, Clifton Associates Ltd. (Clifton), Canada North Environmental Services (CanNorth), and Environmental Dynamics Inc. (EDI).1 The Environmental Act Proposal (EAP) for the Vivian Sand Facility Project written by M. Gifford, P. Biol. R.P. Bio., AECOM Ltd., was submitted to the Manitoba Assessment and Licensing Branch public registry on July 2, 2020.2

One main difference between the projects is that even though Hanson Lake silica sand mine would extract sand from the Winnipeg Formation in Saskatchewan the depositional environment for the sand was different than in the Winnipeg Formation in Vivian Manitoba. The Hanson Lake deposit is overlain by limestone (dolomite) with no intervening shale layer. The sand layer at Hanson Lake does not contain layers of shale. The absence of shale is verified by core logs given in appendix B of the Hanson Lake EIS.1 Since there is no sulphide bearing shale in the Hanson Lake sand acid formation will not occur.3 In the Vivian area a shale layer containing sulphide separates the limestone and aquifer and the sandstone aquifer of the Winnipeg formation.4 The sandstone aquifer as verified by 42 well core logs obtained from Manitoba Groundwater Section contains inter-layered sulphide bearing shale layers.5 The sand in the Vivian area is coated by marcasite, a form of iron sulphide.6,9,12,13 The sulphide in the sandstone aquifer in the Vivian area would oxidize to from acid when exposed to air. Acid formation would mobilize heavy metals.7,8,9,10,11,12,13

****

April 20, 2021

Dear Minister Wilkinson,

I am writing in solidarity with many other Manitobans who would like to see the CanWhite Sands Corporation’s Vivian Sand Extraction and Processing Plant Project designated for a Federal Impact Assessment under the Impact Assessment Act.

Your recent decision not to designate this project has people worried. There are legitimate concerns about the proposal and I urge you to reconsider this decision. The potential risks relate to: changes to the environment, including the quality and quantity of ground and surface water, effects on fish and fish habitat and species at risk, human health, socio-economic conditions, and the rights of Indigenous peoples.

One of the main causes for concern is that the project is based on a new and unproven technology. CanWhite Sands has admitted as much in its submissions and further study is required to assess the technology’s potential interactions with the environment. This uncertainty demands a high level of initial oversight.

Unfortunately, we have a provincial government that has demonstrated a high level of enthusiasm for the project and a low level of concern for its environmental and human consequences. Given the lack of trust in, and the low level of scrutiny by, the Manitoba government in this regard, a Federal Impact Assessment would do a lot to help people in the area feel that their well documented concerns have been given their proper due before the project proceeds.

The advocacy group What the Frack Manitoba has identified a number of ways in which the company’s submissions to your department and other licencing authorities fail to address real concerns about aquifer contamination and the novel engineering principles of the sand extraction process.

Of particular concern is the return to the sandstone aquifer of large amounts of water extracted with the sand by air lift pumps. This aerated water will react with proven sources of sulphide to acidify the aquifer causing the mobilization of heavy metals to further contaminate the aquifer.

Beyond appealing to your own stated concern for the environment and discretionary authority granted to you in this matter as the Minister, I note that this project appears to meet the threshold for an automatic trigger of a Federal Impact Assessment based on CanWhite Sands’ need to transport the processed sand by rail.

According to the Physical Activities Regulations (SOR/2019-285) of the Act, the cumulative impacts of a rail yard with a total area exceeding 50 hectares will be subject to an Assessment. CanWhite Sands Corporation would not be capable of sending their product to market in the quantities they claim in their submissions without the construction of a rail yard larger than 50 hectares.

The Impact Assessment Agency of Canada should conduct an in-depth review of all materials sent to you and the Agency to date, including:

•The LeNeveu report “Evidence for Aquifer and Slurry Line Contamination and Land Subsidence from Vivian Silica Sand Extraction Wells” (47-page) submitted on February 16, 2021 and the related review by Dr. A.R. Ingraffea of Cornell University.

•The “Critique of CanWhite Sands Minor Notice of Alteration, 2021.01.22” (7-page) submitted on February 23, 2021.

•The report “Reasonable Apprehension of Bias by the IAAC and Manitoba Regulators in Non-Designation of the CWS Vivian Sand and CN/CWS Rail Yard Projects” (26-page) submitted on March 30, 2021.

These and any other documents received by your department in this matter should be shared with any other bodies involved in reviewing the project or providing advice to government about the project, whether in previous or future rounds of consultation.

The stakes are high for the environment, the people and the wildlife in the immediate vicinity of the project and beyond. Do not allow the Vivian Sand Project to be a live and largely unsupervised experiment with unproven technology. Leaving the due diligence on the project solely to the current Manitoba government would effectively amount to that.

I close by urging you once again to live up to your responsibility to protect our environment and trigger a Federal Impact Assessment without further delay.

Sincerely,

Daniel Blaikie, M.P.

***

2021 03 30: Reasonable Apprehension of Bias by the IAAC and Manitoba Regulators in Non-Designation of CWS Vivian Sand and CN/CWS Rail Yard Projects by D.M. LeNeveu, B.Sc. (hons. physics), M.Sc. (biophysics), B.Ed. (Queens) On Behalf of What the Frack Manitoba

…

8 Conclusion

There has been reasonable apprehension of bias in favour of the proponent in the Vivian CWS and rail yard projects by the IAAC and Manitoba provincial government authorities. The rail yard required for sand loading for the CWS processing plant is greater than the 50 hectare threshold for an IAAC physical activity. The rail yard project must be designated. The cumulative interacting effects of the CWS sand processing facility, the CWS sand extraction and the rail yard mandate that all must be designated under one joint IAAC designated project. The noise, vibration, light, property value and GHG studies completed for the Vivian Sand Processing Facility Project did not include cumulative effects and are invalid. The provincial Vivian Sand Processing Facility Project must be terminated and recommenced under the one joint IAAC designated project that includes the processing facility, sand extraction, and the rail yard.

The reasonable apprehension of bias indicates regulatory capture by the proponent in both provincial and federal environmental assessment processes. The collusion of the province with the proponent is blatant and reprehensible. The province does not enforce its own Acts and regulations. It ignores and stonewalls public comment that uncovers this behaviour. It conducts a public review process that gives the appearance of due diligence but is designed for approval of all projects. Legitimate issues are ignored or handled through imposition of ineffective licence conditions with little or no enforcement.

It is reasonable to assume that the proponent bias exhibited by the IAAC in the Vivian sand projects to circumvent designation would occur in all designation requests to the IAAC. The IAAC is failing in itsmandate to protect the environment of Canada. It is colluding with proponents to avoid environmental assessment and suppressing disclosure of the collusion. How can the environment be protected if assessments are deliberately avoided? The Agency should be renamed to the Impact Avoidance Agency. A more serious failure of the Agency could not be imagined.

At stake in the projects of this report is the drinking water of a large portion of southeast Manitoba. Water is life. Think of the devastating effects to health, property and businesses if the wells are dried up and contaminated.

A complete resign of the provincial assessment process and the Impact Assessment Agency is required. At the root of the problem is industry led environmental assessment. The professional companies that prepare the environmental impacts are paid to avoid expense to the proponent, and to act in the proponent’s best interests. Bias is exhibited primarily by omission. Any detrimental environmental effects that would be prohibitively expensive to mitigate or cannot be avoided are simply omitted. The regulators are captured by the promise of wealth and jobs and, in some cases, ideologies favouring unbridled free enterprise. We need assessments that are done by arms length expert agencies that are funded by the proponent.

***

Cornell University, College of Engineering

March 3, 2021

To whom it may concern

REF: “Evidence for Aquifer and Slurry Line Contamination and Land Subsidence From Vivian Silica Sand Extraction Wells” a report by Mr. Dennis Leneveu

I have thoroughly reviewed the above-referenced report and my qualifications for so doing are attached to this testimonial.

I can state at the outset that this report is very professionally written, well documented, and evidences very good knowledge of a wide range of related technical issues including mineralogy, well design, chemistry, and regulations. It is clear and compelling to a technical reader.

I found no error in any of the calculations embedded in the report, and fully support the hypotheses for both contamination and subsidence tested by Mr. Leneveu’s analyses of available data. I found only one significant typo in this report: “”The specified sand production rate for the CWS Processing Facility is 1.36 tonnes per year according to the CWS EAP.” This clearly should be 1.36 million tonnes, and Mr. Leneveu’s subsequent calculations are based on the correct value.

In summary, I state that this report should be seriously considered in the decision-making process regarding the permitting of the proposed facility.

Anthony R. Ingraffea, Ph.D. P.E.

Dwight C. Baum Professor of Engineering Emeritus

Distinguished Member ASCE

****

Critique of CanWhite Sands Minor Notice of Alteration, Jan 22, 2021 by D.M. LeNeveu, Feb 23, 2021

***

Report Highlights Evidence for Aquifer and Slurry Line Contamination and Land Subsidence From Vivian Silica Sand Extraction Wells Feb 16, 2021 by D.M. LeNeveu

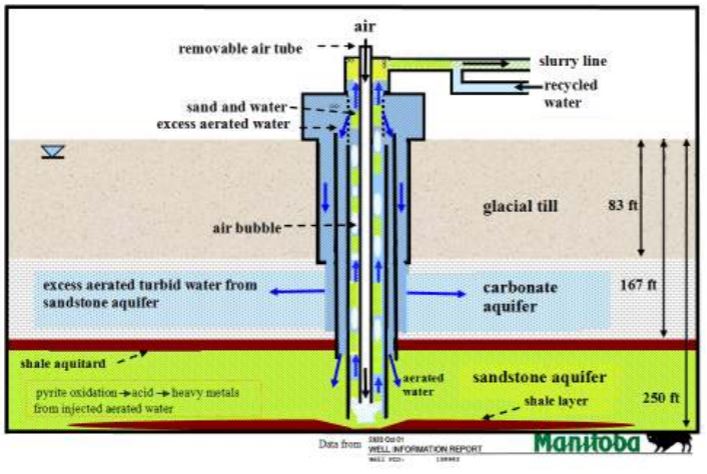

According to information from the well records obtained from the Manitoba Government, excess water from sand extraction in the sandstone aquifer would be pumped via the outer well tube and the open hole below into the carbonate aquifer violating the regulation of the Manitoba Groundwater and Well Water Act prohibiting mixing of aquifer waters.

●The large amount of excess water injected into the carbonate aquifer will result in an unsustainable draw on the sandstone aquifer.

●Marcasite coated sand, pyritic oolite and shale fragments withdrawn in the extraction process will be exposed to aerated water in the air lifting tube. The aerated water will oxidizethe pyrite and marcasite to form acid that will mobilize heavy metals. Excess water returned to the carbonate aquifer will contain some acid, heavy metals and fine sand and silt contaminating the carbonate aquifer and degrading the water quality.

●If aerated excess water were returned to the sandstone aquifer pyrite would be oxidized to form acid that would mobilize heavy metals contaminating the aquifer. Pyrite is in the shale aquitard overlying the sandstone and in shale layers and oolite nodules found in the sandstone. The sand grains in the sandstone aquifer are coated with marcasite (white pyrite) that would also be oxidized when exposed to aerated returned excess water.

●The evidence given in this report demonstrates irreparable damage to both aquifers could occur.

●Contamination in slurry line including highly toxic acrylamide from the beak down of polyacrylamide in the clarifier tank, acid and heavy metals would accumulate in the recycled water of the closed loop system. The accumulation of acid and other contaminants would prevent indefinite recycling necessitating disposal of recycled water. The CWS Environment Act Proposal does not include any reference on how they intend to dispose of contaminated recycled water and potentially acid generating mud cake waste from the clarifier tank and drill mud and cuttings from the numerous CWS extraction wells.

●Since 2017 CWS has received 16 temporary authorizations from the Manitoba Drainage and Water Rights Licensing Branch to pump water to the surface at rates of between 350 to 1500 US gallons per minute. These temporary authorizations imply that water discharge occurred. Discharge has been verified by a June 7, 2019 Google Earth image showing water around CWS sand piles extracted near Vivian, Manitoba.

●Discharged water is liable to be contaminated with heavy metals and acid from oxidation of pyrite in sand by air used to lift the sand from the aquifer. Excess water could have been returned to the formation as well by separate injection wells or sand extraction wells degrading the water quality in the aquifers.

●Extremely toxic acrylamide monomer from the breakdown of polyacrylamide used in the processing plant clarifier tank could enter the water table from slurry line spillage, wash plant leakage and leakage from the French drain system used to collect contaminated water from sand stockpile runoff.

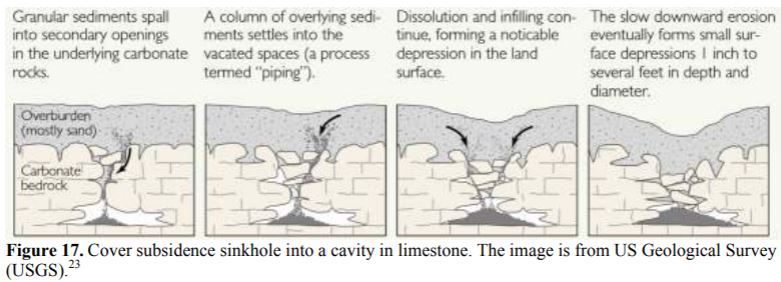

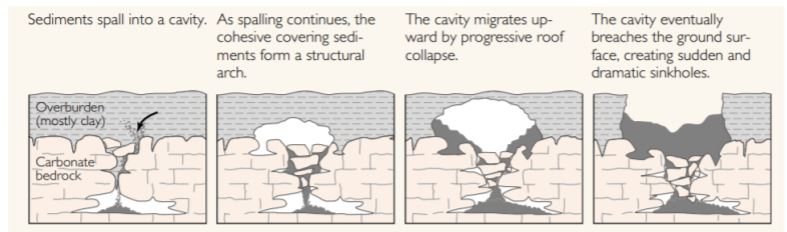

Land subsidence and sinkholes are expected to occur as a result. The occurrence of subsidence and sinkholes would increase each year as the area of CWS wells advance.

●An independent publicly available rock mechanics study should be funded by CPS to evaluate the potential for land subsidence caused by CPS sand extraction.

●Several residents of Springfield Manitoba on Feb.1, 2021, filed a report with the Director of the Manitoba Water Science and Management of suspected violations of the Manitoba Groundwater and Water Well Act. The report includes complaints of deterioration of their well water quality since the start of CWS advanced exploration activities in the area. The results of the investigation into the complaint should be publicly available.

●Slurry lines will extend over a large area outside the plant site. According to CWS high-density poly pipe (HDPE) will be used for the slurry lines. There are many failure modes for the slurry pipe including joint failure, accidental impact, deterioration from UV, embrittlement in winter, and pressure surges from water hammer. Spillage of contaminated water will likely occur during line movement every five days for each new extraction well.

●An independent publicly available baseline survey of trace metal, acrylamide content and water quality in representative wells in both the carbonate and sandstone aquifers over the entire mine claim area should be funded by CWS.

●An independent publicly available geochemical analysis on representative core samples taken over the entire CWS claim area should be funded by CPS. The analysis of the sand, shale and oolite should include an acid-base accounting test and heavy metal content.

●The Winnipeg aqueduct which crosses the CWS mineral lease area is known to leak. When slurry lines approach within drainage distance of or cross the Winnipeg aqueduct, the aqueduct water should be regularly sampled for acrylamide, heavy metals and change of water quality.

●Prior to commencement of advanced exploration activities that according to the drilling records substantially began in 2018, CWS did not file a mine closure plan and financial assurance with the Director of the Manitoba Mines Branch as required by the Manitoba Mines and Minerals Act.

●The legally required mine closure plan was not submitted as part of the CWS Environment Act Proposal of July 2, 2020, for the CWS processing facility. The public and the TAC did not have the opportunity to review the mine closure plan that should have contained essential information on protection of the environment, rehabilitation and minimizing hazards to public safety as required by the Manitoba Mines and Minerals Act.

Evidence for Aquifer and Slurry Line Contamination and Land Subsidence From Vivian Silica Sand Extraction Wells by D.M. LeNeveu, M.Sc. (biophysics), B.Ed., B.Sc. (hons. physics), Feb 16, 2021, on behalf of What the Frack Manitoba

Overview HD Minerals/CanWhite Sands Inc. (CWS) plans to extract silica sand from the Winnipeg Formation aquifer that together with the overlying carbonate aquifer supplies water to a large portion of south east Manitoba. The sand is to be extracted using air lift wells that would withdraw a mixture of air, sand and water from the sandstone aquifer of the Winnipeg Formation. Excess aerated water is to be returned to the formation. The sand is to be delivered to the CWS Vivian Sand Processing Plant by means of closed loop slurry lines. The sand is to be stockpiled and processed at the plant at Vivian, Manitoba, township SE32-10-8E. Silt and fine sand are to be removed in a clarifier tank at the processing pant and the water returned to the remote extraction locations to pick up more sand. A large number of extraction wells will be drilled to deliver 1.36 million tonnes of silica sand per year to the processing plant. After up to five days of extraction each well is to be sealed. The lifetime of the project is expected to be 24 years. CWS has over 80,000 hectares of mineral claims for sand extraction as shown in Figure 1. Not included in Figure 1 is the potential CWS extraction of silica sand from existing or future quarry leases over a larger area.

Figure 1. CWS mineral claims

2. Executive Summary

Mr. Somji, President and CEO of CanWhite Sands, in a letter to the Impact Assessment Agency of Canada (IAAC) of September 11, 2020 described the configuration of the CWS triple tube silica sand extraction well.1 Air is to be introduced through an inner tube that is shorter than the surrounding second extraction tube so that air should stay in the extraction tube. Sand and associated water is to be withdrawn through the second extraction tube assisted by air lift from the air injection tube. Excess water is to be returned to the formation through the outer tube. Sand is to be pumped into a slurry line for delivery to the CWS silica sand processing facility near Vivian, Manitoba.

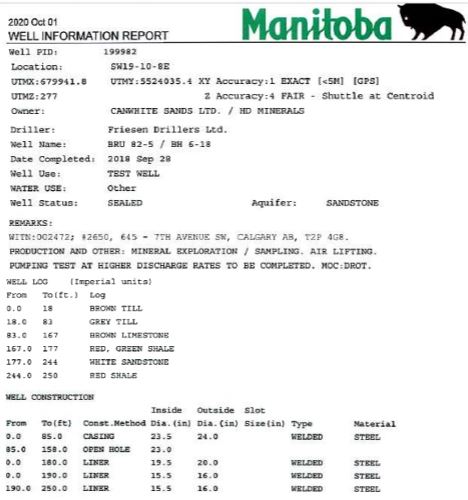

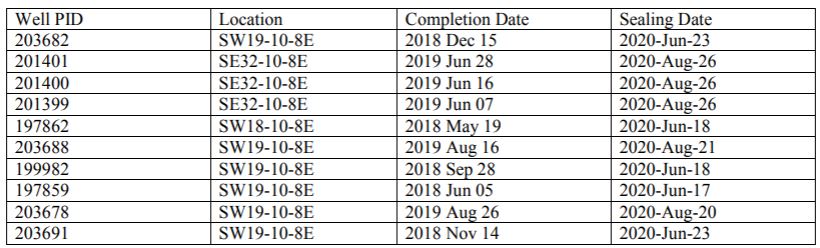

The construction, sealing and core logs of 42 CWS wells is given in Friesen Drillers well information reports obtained from Manitoba Groundwater.2 Two of these wells with PID numbers of 199982, 197863 completed in the summer of 2018 at the Centre Line Road site township location SW19-10-8E where sand was extracted by CWS were indicated to be “air lifting” in the well records. Other wells at this site may have been also used for air lift sand extraction.

Excess water from air lift sand extraction is to be returned to the formation. Excess water must be injected into either the sandstone aquifer or the carbonate aquifer or both. The outer tube of air lift wells 199982 and 197863 terminate at the top of the carbonate aquifer with an open hole extending beneath. The outer tube of 8 other wells at the Centre Line Road site also terminate near the top of the carbonate aquifer with open hole extending beneath. It appears that these wells are constructed to inject excess water withdrawn with the sand into the carbonate aquifer. The mixing of water from separate aquifers would be a violation of the Manitoba Groundwater and Water Well Act. 13 A large amount of water injected into the carbonate aquifer would result in an unsustainable draw on the sandstone aquifer.

Excess water returned to the sandstone aquifer would be aerated from the air lift process. Air in the excess water would react with pyrite in the shale aquitard and shale layers and with marcasite (white pyrite) and pyritic oolite nodules in the sand generating acid. The presence of marcasite in the sand has been verified by certified laboratory results of samples of CWS extracted sand. Acid would mobilize toxic heavy metals in the shale and sand contaminating the sandstone aquifer.3-12

If all the excess water is pumped into the carbonate aquifer that water would be laden with fine sand and silt from the sandstone aquifer changing the water quality. If excess water were pumped into both aquifers the water in both aquifers would become contaminated with acid and heavy metals. If excess water were pumped into the sandstone aquifer only, the sandstone aquifer would become contaminated with acid and heavy metals. 3-12

In the slurry line acid would form from oxidation of marcasite in the sand and from oxidation of pyrite in shale fragments and oolite nodules withdrawn with the sands. The acid would mobilize heavy metals into the slurry line water. Acid and heavy metals would also be withdrawn from the sandstone aquifer into the slurry lines if aerated excess water is returned to the sandstone aquifer. Acid and heavy metal bearing waste such as mud cakes from the clarifier tank in the processing plant and drill mud and cuttings from the numerous wells would require specialized disposal. Contamination in slurry line including highly toxic acrylamide monomer from the beak down of polyacrylamide in the clarifier tank, acid and heavy metals would accumulate in the recycled water of the closed loop system. The CWS EAP specifies the recycled water of the closed loop system is to be stored in an onsite tank over winter to avoid disposal. Eventually the recycled water would be too contaminated and too acidic to be used in the wash plant and would require disposal in an engineered tailings pond facility. The CWS EAP does not include any reference to disposal of waste or contaminated slurry line water that would be necessary over the 24 year lifetime of the project.

Figure 2 illustrates the scenario for aquifer and slurry water contamination and unsustainable draw on the sandstone aquifer for well PID 199982 at Centre Line Road.

Figure 2. Aquifer and slurry water contamination scenario from interpretation of CWS well drilling record ID 199982 obtained from Manitoba Groundwater Section.

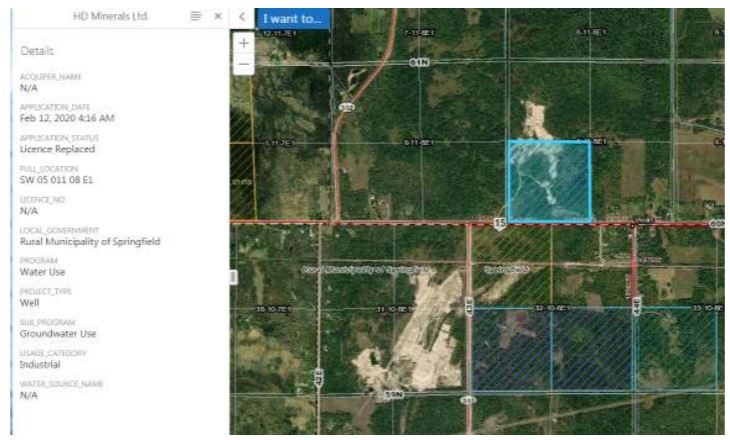

CWS well 203699 was completed on Aug. 9, 2019 in or near the LSL sand and gravel quarry at the junction of Oakwood Road and Highway 302, township location NW19-11-8E. The Manitoba Drainage Rights online water portal shows a temporary authorization for water use for HD Minerals/CWS at a second sand and gravel quarry near the junction of Highway 15 and Highway 302 less than one kilometre from the town of Vivian Manitoba (Figure 15). Local residents observed extracted silica sand piles in October 2021 at this location (Figure 16). There is no well record for the CWS silica sand extraction wells at the quarry near Vivian. Both these quarries are outside the CWS mineral claims and not part of the approvals process for the CWS Vivian Sand Facility Project and the upcoming CWS Vivian Sand Mine and Extraction Project under the Manitoba Environment Act. Unregulated contamination and mixing of aquifer waters could occur from CWS silica sand extraction wells over quarries throughout the extent of the Winnipeg formation.

Five wells completed in June 2019 at the site of the proposed Vivian sand processing plant are in the well records. Some of these wells have been used for silica sand extraction. Excess water extracted with sand at the Vivian site may have been returned to the formation or discharged on surface. The well records indicate excess water may have been returned to the carbonate aquifer in one well.

Since 2017 CWS has received 16 temporary authorizations from the Manitoba Drainage and Water Rights Licensing Branch to pump water to the surface at rates of between 350 to 1500 US gallons per minute. These temporary authorizations imply that water discharge occurred. A Google Earth image from June 7, 2019 shows piles of extracted sand surrounded by water at the Vivian location SE32-10-8E confirming surface discharge occurred (Figure 14). Discharged water from airlift sand extraction is liable to be contaminated with heavy metals and acid from oxidation of pyrite by air injected into the sandstone aquifer.

Surface discharges that occurred during exploration could also occur during production from leakage and spillage from CWS slurry lines and from the wash plant. As new wells are drilled about every five days, the slurry lines must be continually emptied and moved increasing the risk of spillage and leakage. Extremely toxic acrylamide monomer from the breakdown of polyacrylamide used in the processing plant clarifier tank could enter the water table from spillage.14

The well information records report sand collapsed into open holes drilled in the sandstone in two of the CWS air lift wells. Sand collapse indicates that sand will creep into extraction cavities decreasing the area of support for the overlying shale aquitard. The unsupported area of shale aquitard will likely eventually collapse into the cavities. Overburden pressure and the process of shale slaking would facilitate this collapse.48,49 Land subsidence and sinkholes would be expected to occur as a result as shown in Figure 17 and Figure 18 and as illustrated on the cover page. The subsidence and sinkholes would increase each year as the area of CWS wells advance.

The required mine closure plan for this Project that should have been filed before commencement of advanced exploration in accordance with the Manitoba Mines and Minerals Act must include measures to minimize contamination of the aquifers and land subsidence. Provision of financial assurance to the Crown for rehabilitation must be provided.15 The Mines and Minerals Act regarding the mine closure plan has not been enforced by the Manitoba Mines Branch despite a July 22, 2020 letter from Don Sullivan spokesperson for What the Frack Manitoba to the Manitoba Minister of Agriculture and Resource Development asking for compliance with Act. The failure to enforce the requirement for a mine closure plan was also included in the submission by D.M. LeNeveu to the CWS processing facility environmental review process under the Manitoba Environment Act.12

Several residents of Springfield Manitoba on Feb. 1, 2021, filed a report with the Director of the Manitoba Water Science and Management of suspected violations of the Manitoba Groundwater and Water Well Act.13 The report includes complaints of deterioration of their well water quality since the start of CWS advanced exploration activities in the area. The suspected violations of the Manitoba Groundwater and Water Well Act include,

- contaminating and adversely affecting the quality of groundwater in the area of a well or test hole,

- allowing the interconnection or mixing of groundwater between the Winnipeg Formation and the overlying aquifer,

- failure to adequately emplace annular sealing at the time of well construction,

- failure to affix a well identification tag,

- failure to properly secure well covers,

- failure to issue separate well construction and sealing reports within the required time period, and

- failure to protect the sandstone aquifer of the Winnipeg formation from unsustainable draw.

We recommend this project be immediately halted until the mine closure plan and the investigation into suspected violations of the Manitoba Groundwater and Water Act are completed and made publicly available for the review process under the Manitoba Environment Act. The mine closure plan must address all processing and extraction risks, including the risks described in this report. We recommend a full public panel review process hearing for both the silica sand processing facility and the mining extraction be undertaken under a quasi-judicial independent body such as the Manitoba Clean Environment Commission. The mine closure report and the findings from the investigation of suspected violations of The Manitoba Groundwater and Well Water Act must be provided for the panel review process.

3. Approval Process

Under the Manitoba Environment Act, CWS Environment Act Proposal (EAP) for the CWS Vivian Sand Processing Facility was filed in the public registry 6057.00 on July 2, 2020.26,29 The information filed in the EAP was restricted solely to the processing facility. In the EAP no detailed engineering drawings with dimensions of buildings and details of wash plant or dry plant operations were given. Extraction activities that would have an implication on the operation and design of the processing facility were omitted. The EAP states,

“A separate Environment Act licence application will be submitted later this summer for the silica sand extraction activities that will supply the Processing Facility with sand (‘Extraction’). Extraction will involve temporary water well drill holes that are located on small sites for relatively brief periods of time. Water and sand exist naturally together in the formation and, assisted only by injection of air, they will flow to the surface as slurry. The slurry will be transported to the Processing Facility using a moveable slurry line, which will be re-located from site to site as the water well drilling rigs relocate. The slurry line will be included in the project description for extraction. CanWhite’s permanent buildings, facilities and infrastructure are part of this sand Processing Facility Project and are included in this application.”

The sandstone formation from which the sand is to be extracted is known to have sources of pyrite. In a wet environment, pyrite will react with air to form acid.3,4,5 The acid can mobilize heavy metals causing contamination. This is a well known problem in mining called acid drainage.5 The brief disclosure in the CWS EAP of air injection to the aquifer is gravely concerning. I described in my submission to the Manitoba public review of the CWS processing facility, how the injection of air would react with the pyrite in the formation causing heavy metal contamination of the aquifer.12 I reported that shale fragments and pyritic oolite was observed by local residents in sand piles near Vivian extracted by CWS during advanced exploration activities as shown Figure 3.

Figure 3. Shale fragments interspersed in CWS extracted sand near Vivian Manitoba

Samples of sand taken by residents were sent for analysis in an accredited laboratory. The analysis showed the presence of sulphide in the sand. From other reports the sulphide is known to be from marcasite (white pyrite) coating the sand grains.7,11 The sources of pyrite extracted with the sand will be exposed to air and transported in the slurry lines to the CWS processing facility. The formation of acid and heavy metals would affect the operation of the facility and may require the necessity of engineered tailings ponds for the disposal of acid mine waste from the facility such as mud cakes from the clarifier tank and drill mud and cuttings from the numerous CWS wells. An engineered tailings facility was not included in the CWS EAP for the Vivian Sand Processing Plant.

The evidence I submitted to the Manitoba public review process for CWS processing facility was also submitted to the Impact Assessment Agency of Canada (IAAC) as part of a request for designation of the CWS Vivian Sand Project for a federal environmental review under the Impact Assessment Act. To counter the information presented in my submission and other submissions to the Manitoba public review and to the IAAC, Mr. Somji, CEO of CanWhite wrote a letter to the IAAC on Sept. 11, 2020.1 His letter was posted in the public registry 6057.00 for the CWS Vivian Sand Facility.

The IAAC did not designate the Vivian Sand Facility Project for federal impact assessment mainly due insufficient information provided in the Vivian Sand Processing Facility Review Process.1 Federal designation may be reassessed based on the completeness of information provided by the proponent for the upcoming CWS mine extraction approval under the Manitoba Environment Act. The CWS mine extraction process will not under go an independent technical review under the Clean Environment Commission of Manitoba. This report is being submitted in advance of the Manitoba approvals process for the CWS Mine Extraction Project in an endeavour to ensure that the important technical information documented here is fully addressed.

4. Excerpt from Mr. Somj’s Letter of September 11, 2020 to the IAAC

Mr. Somji’s letter to the IAAC of September 11, 2020 states;1

“Water well drillers around the world, and more specifically in Manitoba, utilize air to clean out sand from newly drilled and producing water wells. This method has been used for over 50 years and is proven to not harm the formation or water quality. Building upon this process CWS has developed a patented sand lift system where sand is brought to surface with air and associate aquifer water is left in the aquifer. A net zero solution, CWS has proven the ability to not remove aquifer water while harvesting the sand, therefore there is no anticipated water draw from the aquifer or need for water disposal or discharge at surface.

On private lands under access agreement, a standard 25 cm well is drilled to formation and cemented in place to preserve the existing aquitard. A second 15 cm extraction tube is placed inside the wellbore to the formation. Inside the 15 cm extraction tube an air introduction tube is placed. The air introduction tube is shorter than the extraction tube so the air stays within the extraction tube. As air is introduced into the extraction tube it immediately rises to surface. This movement creates momentum to the surface bringing up the associated fluid and solids. The movement creates a suction effect at the bottom of the extraction tube due to a natural lower pressure inside the extraction tube versus the natural pressure of the geologic formation. This pressure differential allows the formation to “push” the sand into the extraction tube. The end result is very similar to drinking a slush drink with a straw. As the sand is removed the associated water returns to the formation through the annular space between the 25 cm and 15cm tubing. At no time is the formation subject to overpressure and as the sand is delivered wet no dust is generated.

The Harvest process takes an estimated 5 days per well after which the wells are abandoned under the standards defined by the Manitoba’s Mines and Minerals Act, Drilling Regulation, 1992, and the surface is immediately remediated. As the harvest sites are temporary and portable, the site returns to its natural state within weeks of CWS harvest completion. No traditional mining activities take place and therefore there are no open pits and no underground operations.”

No data, references or evidence were submitted to support the information in Mr. Somji’s letter to the IAAC. Mr. Somji’s letter was submitted at a time when no response from the public or the Technical Advisory Committee could be made via the Manitoba environmental review process under the Manitoba Environment Act. A rebuttal to Mr. Somji’s letter I submitted to the IAAC could not be filed on the Manitoba Public Registry for the project because the public comments period had already closed.6

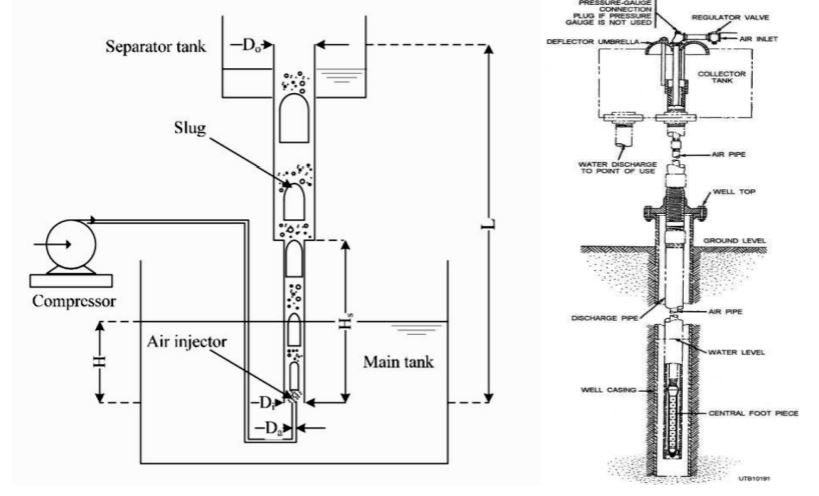

5. Air Lift Pumps

Air lift pumps have long been used for dredging, sludge pumping, deep sea metallic nodule mining and other uses.16 In dredging and deep sea-mining operations the air-lift pump tube must be moved to achieve sediment removal. A schematic of a typical air lift pump illustrating the air lift bubbles is shown in Figure 4a. The air injection tube is external to the extraction tube in Figure 4b. The size of the bubbles increases as they rise due to the drop in fluid pressure. In Mr Somji’s description the air injection tube is within the extraction tube as shown in Figure 4b. In Figure 4b, as in Mr. Somji’s description, air injection occurs above the end of the extraction tube so that air remains within the extraction tube.

Figure 4. a. Schematic of a typical air lift pump from Hanafizadeh and Ghorbani, 201116 b. air lift pump showing central air tube and foot piece for air dispersion17.

Excess water extracted with the sand according to Mr. Somji’s Sept. 11, 2020 letter to the IAAC is to be returned to the formation through an outer well tube. Returning the excess water to the sandstone aquifer would be problematical. Much of the returned excess water would likely be sucked in with the sand in the adjacent extraction tube. To avoid this problem the design of many CWS wells have the outer tube terminating just below the start of the carbonate aquifer. A drilled open hole penetrates into the carbonate aquifer terminating above the shale aquitard. With this configuration returned water would enter the carbonate aquifer above the impermeable shale layer thus avoiding the problem of being sucked into the sand extraction tube in the sandstone aquifer. The much higher transmissivity of the carbonate aquifer makes it more suitable for excess water return than the sandstone aquifer.44 Excess water returned to the carbonate aquifer, would carry fine sand and silt in some cases heavy metals and acid from pyrite oxidation in the sandstone aquifer. Sandstone aquifer water would be intermingled with the carbonate aquifer water which is not allowed according to the Manitoba Groundwater and Water Well Act Regulations.

6. Well Record for Triple Tube Air Lift Extraction Well ID 199982

In the well records for CWS wells there are four drilling reports for a triple tube air lift extraction well, located at the Centre Line Road Site.2 The drilling report for well 199982 is reproduced in Figure 5.

Figure 5. Friesen drilling record for triple tube air lifting well ID 199982 from Manitoba Groundwater

The configuration of triple tube air lift extraction well of Figure 2 and Figure 5 does not conform to the description in Mr. Somji’s letter to the IAAC of Sept. 11, 2020. The outside diameter of the extraction well tube is given as 24 inches, much larger than the outside diameter of 25 cm. (9.8 inches) given in Mr. Somji’s letter. The inner 16 inch diameter steel tube of well 199982 extends into a red shale layer. Red shale fragments from the hole drilled six feet into the red shale layer are likely to be extracted with the sand. Shale fragments have been observed in the CWS extracted sand piles by local residents as shown in Figure 3.

A removable tube was likely used to inject air into the inner 16 inch diameter steel tube as shown in Figure 2. Otherwise the 16 inch diameter steel tube would have injected air directly into the sandstone far below the second 20 inch diameter steel tube that terminates three feet below the shale aquitard. Such a configuration would have violated the assertion in Mr. Somji’s Sept. 11 letter that the air introduction tube is shorter than the adjacent extraction tube.

The 24 inch diameter outer tube terminates at 85 feet below ground surface two feet below the start of the limestone. A 23 inch diameter open hole extends 73 feet into the limestone below the outer tube. This configuration indicates that the well was designed for excess water taken from the sandstone aquifer to be injected the carbonate aquifer.

The second twenty inch diameter tube terminates three feet into the white sand layer. Excess aerated water could be injected into the sandstone from this tube. Excess water according to the design for well 199982 could be injected into both aquifers. Air in the excess water injected into the sandstone would oxidize the pyrite in the shale aquitard immediately above and the marcasite in the sand. Excess water injected near the top of the sandstone could act to push sand toward the extraction tube terminating in the red shale layer below. This aerated water would eventually contact and oxidize the red shale layer. A photograph of well 199982 taken in the spring of 2020 before it was cut off and sealed is show in Figure 6.

Figure 6. CWS triple tube air extraction well 199982/002472 at Centre line Road site and an unidentified well Centre Line Road showing visible surface sealing between the outer casing and the adjacent inner casing.

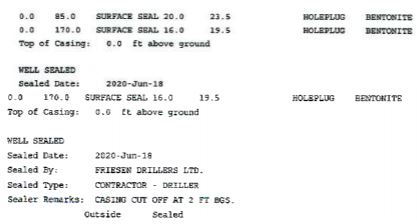

Note that sealing of well 199982/002472 did not occur until June 18, 2020, almost two years after completion in September 28, 2018. Sealing outside the external casing and inside the tubes did not appear to occur until June 18, 2020 according to the records. The fact that the three tubes remained open and unsealed until the sealing date of June 18, 2020 is verified by the photograph of Figure 6 taken May 31, 2020. The surface of the water table was visible inside the unsealed tubes. An unidentified well with no well tag and visible surface sealing between the outer and adjacent steel casing is also shown in Figure 6 at the Centre Line Road site. The photograph of the unidentified second well of Figure 6 verifies that if well 199982 had annular sealing between the steel casings, it would have been visible.

The casings for well 199982/002472 were cut off two feet below ground upon sealing on June 18, 2020. Combining the sealing report and the well construction report long after the completion of the well is a violation of the Manitoba Groundwater and Water Well Act.13 This violation makes it impossible to determine when the annular sealing between the triple tube casings was emplaced by means of the well information report. The well photograph, witness accounts and a photograph of another well with annular sealing between the outer and adjacent steel tubes establishes that the annular spacing between steel casing in well 199982 were open and functional at the time of sand extraction.

Well 199982 had no affixed well tag. The well was identified as PID 199982 WINT 0002472 by the unique triple tube diameters in the well records that match the measurement shown in Figure 5. Both wells shown in Figure 6 as well as many others at the Centre Line Road site were left improperly covered. Mr. Somji in his letter to the IAAC of Sept. 11, 2020 claimed that vandalism occurred on CWS unattended drill sites. Figure 6 shows the cover for the inner tube was partially welded on. Specialized equipment such as a cutting torch would have been required to remove well covers over the outer well tubes. Attributing the lack of proper covering of the well to vandalism is not credible. Inadequate well covering and failure to affix well tags are violations of Well Standards Regulation 21/2015 of the Manitoba Groundwater and Water Well Act.13

The aquifer contamination scenario for the triple tube configuration corresponding to well ID 199982 in the Friesen drilling records for CWS wells is shown in Figure 2.

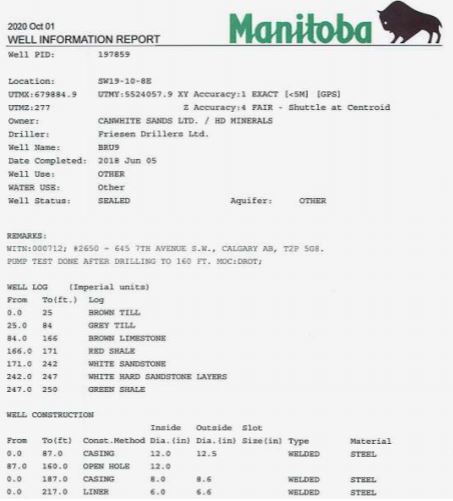

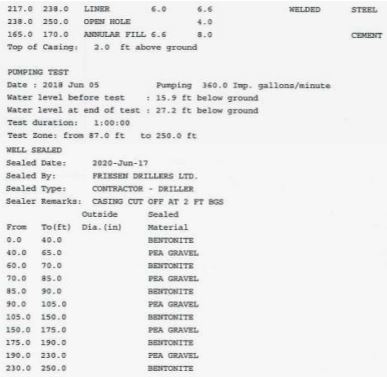

7. Well Record for Triple Tube Air Lift Extraction Well ID 197859

Well 197859 at Centre Line Road is similar in construction as 199982 with three nested steel tubes. The outer 12.5 inch diameter tube terminates three feet below the start of the limestone with 12.0 inch diameter open hole beneath until 6 feet below the termination of the limestone. The second 8.6 inch diameter tube terminates 15 feet below the shale aquitard in the white sand layer. The third 6.6 inch diameter tube extends to a depth of 238 feet terminating 4 feet above the bottom of the white sand layer. An open hole is drilled further through a hard white sand layer and a layer of green shale. The well information record for well 197859 is reproduced in Figure 7.

Figure 7. CWS Triple tube air lift sand extraction well 197859 at Centre Line Road

Well 197859 is not designated as air lifting in the remarks section as was well 199982. The construction of well 197859 is similar to 199982 indicating both were air lift wells used for the sand extraction with a removable air injection tube. An annular cement seal was emplacement at a depth of 165 to 170 feet at the level of the shale aquitard. The cement seal across the aquitard would prevent interchange of aquifer water across the aquitard as is required by the regulations of the Manitoba Groundwater and Water Well Act and would prevent discharge of excess water into the sandstone aquifer. No sealing is shown external to the 8.6 diameter steel liner across the aquitard. According to the well information report the outer tube and the open hole below into the carbonate aquifer remained unsealed at the time of construction. Well 197859 appears to be designed to discharge excess water into the carbonate aquifer thus mixing aquifer waters. The pump rate of 360 imperial gallons per minute indicates that a large draw would occur on the sandstone aquifer.

The 197859 well information report shows sealing did not occur until June 17, 2020 more than two years after completion. The annular placement of alternating layers of bentonite and pea gravel sealing material is not given. Reporting surface sealing and well construction information together in the same report two years after the completion date is a violation of Wells Standards 215/2015 of the Manitoba Ground Water and well Water Act.

Well 203682 at Centre Line Road completed on Dec. 15, 2018 has three steel tubes. The outer 20 inch diameter tube terminates at 85 feet deep at the start of the limestone layer. Inside the outer tube is 16 inch diameter tube terminating at 115 feet in the limestone which terminates at 161 feet. Below the outer 20 inch diameter tube a 19 inch diameter open hole extends the remaining length of the well terminating in a 18 foot thick shale layer at 263 feet deep. Two regions of cement annular fill are indicated one terminating at 115 feet deep and the other at 170 feet at the end of the shale aquitard. A comment states an 11 foot cement plug was placed at 164 feet just below the start of the shale aquitard. The sealing does not specify which annuli the cement seals were emplaced. A 10 foot diameter inner steel casing penetrates from the surface to 204 feet followed by a well screen from 204 feet to 245 feet. The sandstone layer extends from 171 feet to 245 feet. The well was sealed on Aug. 23, 2020. The seal emplacement location is not specified. If this well were used for air lift sand extraction it appears to be constructed to allow water return in the carbonate aquifer. The lack of information on the placement of the cement seals makes it impossible to determine the configuration for excess water return.

The report for well 197863 at Centre Line Road SW19-10-8E indicated as air lifting, shows a double tube well with the four inch diameter inner steel tube terminating 12 feet into an unusual 86 foot thick multi shale aquitard layer. This well shows only a thin two foot layer of sandstone before a seven foot layer of mixed sand and shale layers followed by a 58 foot thick layer of white shale and a ten foot layer of black sandstone terminating in granite 326 feet below the surface. Similar to well197862 around the inner liner presumably for air injection into the sandstone aquifer by a removable air tube is a five inch diameter open hole to a depth of 326 feet. An 8.6 inch diameter steel outer casing extends 86 feet terminating two feet into an 81 foot thick limestone layer. A cement surface seal extends to 80 feet followed by annular fill to 160 feet. Two shale traps are given at the level of the shale aquitard. The placement of the surface seal and annular fill is not given. Similar to well 197862, the construction of well 197863 indicates that excess water from sand extraction would be discharged into the carbonate aquifer through the open hole penetrating the limestone layer below the outer well tube. The sand layer in well 197863 is only 7 feet thick mixed with shale layers. Any sand extracted by this well would have a large amount of shale fragments intermixed.

Well 197863 with no significant white sand layer demonstrates the wide variation in white sand thickness and shale layer location within the sandstone aquifer. The pervasive presence of shale below the aquitard contradicts Mr. Somji’s assertion in his Sept.11th letter to the IAAC that pyrite is never present in the white sand layer. Well 197863 is labelled as active. The information record 197863 indicates that CWS wells might not always be properly sealed allowing the potential for surface contamination including fecal matter to penetrate into the carbonate aquifer.

The outer well tube of six other wells at Centre line Road, 200818, 204173, 233688, 203678, 203682 and 203691 terminates near the start of the limestone layer with open hole beneath. These wells all are designed to potentially return excess water to the carbonate aquifer. All have an inner tube extending into the white sand layer below the shale aquitard except well 203678 that has an open hole extending into the white sandstone layer.

In summary all nine wells in the record for Centre Line Road are designed to allow excess water extracted with silica sand to be pumped into the carbonate aquifer depending on the nature of the annular sealing. Air is likely to be introduced by a central tube that is removed after air injection and is therefore not shown in the well construction. The documentation of the location and timing emplacement of annular sealing is not adequate to determine the potential for excess water return to the formation. Excess water from sand extraction wells with sealed annular spaces would be discharged to the surface. One well 199982 may be constructed to allow excess water to be pumped into the sandstone aquifer. Pumping into the carbonate aquifer water withdrawn with the sand from the sandstone aquifer violates Well Standards Regulation 21/2015 the Manitoba Groundwater and Water Well Act.

8. Other wells designated as air lift in the well records

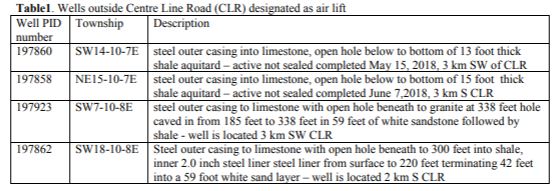

Table 1 gives the information on other wells designated in the well records as “air lifting”

Table1. Wells outside Centre Line Road (CLR) designated as air lift

Wells 198760, 197858 and 197923 were constructed with no means to discharge excess water from sand extraction in to the formation. Excess water extracted during sand air lifting would have been discharged to surface or returned to the formation through a separate injection well. Well 197862 was constructed so that excess water from sand air lifting could have been discharged via the annular space between the outer casing and the liner into the carbonate aquifer. Wells 197860 and 197858 are still labelled as active and not completely sealed more than two years after completion. These two wells further illustrate CWS wells might not always be properly sealed allowing the potential for surface contamination including fecal matter to penetrate into the carbonate aquifer. The open hole in well 197923 caved in illustrating the sand pillars separating the cavities from sand extraction will likely gradually slump into the cavities increasing the unsupported area above increasing the risk of subsidence

9. Water draw on the sandstone aquifer

Excess water extracted with sand from the sandstone aquifer and returned to the carbonate aquifer could create an unsustainable draw on the sandstone aquifer once the CWS continuous mining of sand begins.

The water to sand volume flow rate has been reported to be between 1.4 and 2.5 for a conventional air lift pump for sand extraction. There is no intended water discharge in the closed loop water recycling system for the proposed CWS sand processing facility except for the 15% water in the sand stockpiles reported in the CWS EAP. The 0.15 water to sand ratio in the sand stockpiles is small compared to the expected water to sand ratio extracted by the air-lift well thus almost all water extracted with the sand would be returned to the formation. The specified sand production rate for the CWS Processing Facility is 1.36 million tonnes per year according to the CWS EAP. Based on a dry sand density of 1.65 tonnes per cubic meter and a water to sand extraction ratio of 1.4 to 2.5 (from Srodowiska et al., 2018),18 about 1.5 million cubic meters of contaminated water per year could be pumped into the carbonate aquifer from the sandstone aquifer.

An email of Jan.19, 2020 from the Manitoba Drainage and Water Rights Licensing Branch stated,

“I can confirm that HD Minerals Ltd./CanWhite Sands has submitted 16 requests for Temporary Authorizations in order to complete a borehole and hydrogeological testing program as part of their mineral claims in various areas throughout the province since 2017. The Temporary Authorizations (not Water Rights Licenses) provided permission to drill exploration wells and conduct short-term pump testing. Authorizations were issued for time frames of several weeks to several months. Pumping rates ranged from 350 USgpm to 1500 USgpm. Only two (2) of these authorizations remain active and the remaining fourteen (14) are completed and have expired.”

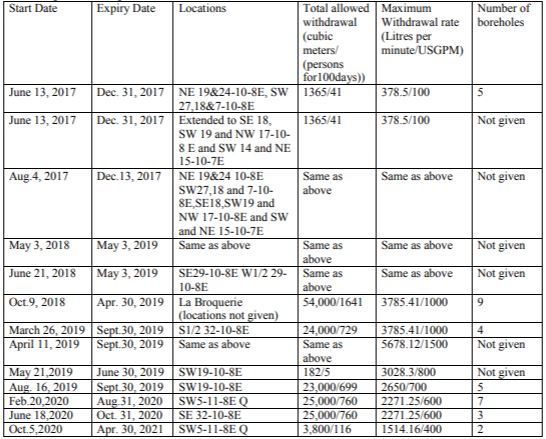

Copies of letters from The Manitoba Drainage and Water Rights Licensing Branch to personnel from HD Minerals/CWS authorizing the withdrawal and diversion of water from CWS testing boreholes in Springfield, La Broquerie and for a quarry near Vivian outside the CWS claim area have been obtained. A summary of the information in the letters is given in Table 2.

Table2. Summary of the information in the temporary authorization letters from Manitoba Drainage and Water Rights Licensing Branch.

The Temporary Authorizations require that CWS correct any water supply problems or provide temporary water supply to anyone whose well(s) are negatively impacted as a result of pumping. Q indicates quarry near Vivian outside the CWS mineral claim area.

The well information record for triple tube well 197859 at Centre Line Road SW19-10-8E gives a pump rate on June 5, 2018 of 360 IGPM (432 USGPM). This pump rate is consistent with the rates given in the email from the Manitoba Drainage and Water Rights Licensing Branch and verifies the large rates at which water and sand will be withdrawn.

An average of three CWS wells operating concurrently for 220 days a year would withdraw a total of from 0.4 to 1.8 million cubic meters of excess water per year at the rates given in the email from Manitoba Drainage and Water Licensing Branch and confirmed by the data in Table 2. The email verifies the large amount of contaminated water that could be withdrawn from the sandstone aquifer and injected into the carbonate aquifer. About 200,000 cubic meters of water per year would also be drawn from the sandstone aquifer for the 15% water in the sand stockpiles at the processing plant. A loss of more than one million cubic meters of water per year would be far beyond the sustainable limit of the sandstone aquifer.19,20 Such a large draw would irreparably damage the sandstone aquifer in violation of Manitoba Groundwater and Water Well Act.

Even if the excess water were returned to the sandstone aquifer during extraction, the aerated water would react with pyrite in the aquitard and the sandstone. Oxidation of the pyrite would create acid and mobilize heavy metals extensively contaminating the sandstone aquifer.3,4,5

The email from Manitoba Drainage and Water Licensing Branch verifies that water has likely been discharged to the surface during advanced exploration activities. This discharged water may have been contaminated with acid and heavy metals from the reaction of injected air with sources of pyrite in the sandstone aquifer or by reaction with marcasite and shale fragments in the shale from sand extracted with the dischargedwater.3-12 The required mine closure plan for the entire CWS Vivian sand project should have specified actions to minimize the risk from this potential contamination.

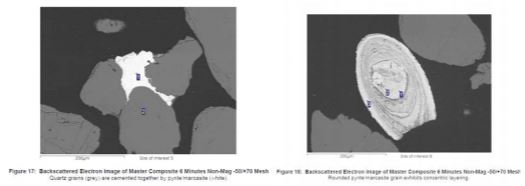

10. Evidence for Marcasite in Sand Extracted by CWS

The sand taken from the Winnipeg formation near Seymourville was found to contain marcasite a form of pyrite. The marcasite found at Seymourville is consistent with the paper by Schieber and Riciputi (2005) on the diagenesis of marcasite throughout the Winnipeg formation. The same process for marcasite diagenesis during the Ordovician era would be expected to occur in the sandstone throughout the CWS claim area. The marcasite in the sand is shown in microscope pictures from the 2014 NI 43-101 technical report of Claim Post Inc. reproduced in Figure 8.7

Figure 8. Electron microscope pictures of marcasite (a form of pyrite) between sand grains from the Winnipeg Formation near Seymourville.

The marcasite in Figure 8 is shown in white. Pictures in Figure 8 were reproduced from the 2014 NI43-101 technical report of Claim Post Resources.

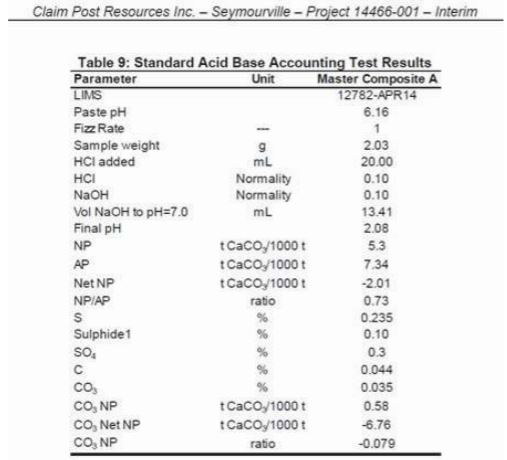

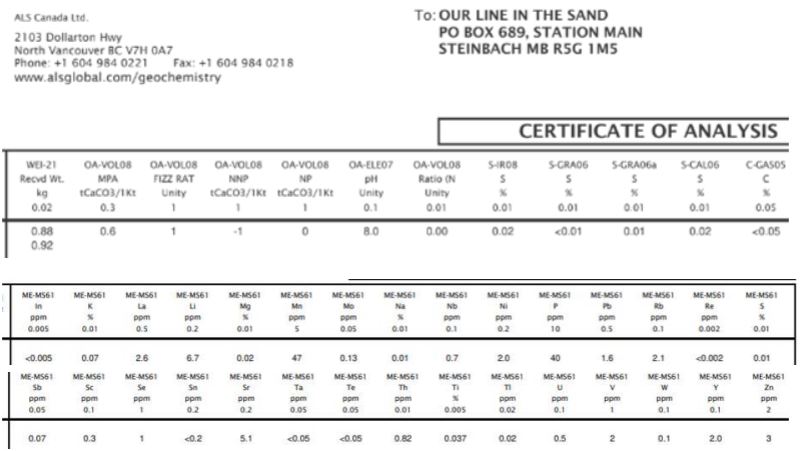

The results of the acid base accounting test for the sand at Seymourville is shown in Figure 9 below.

Figure 9. Acid base accounting results from Winnipeg formation sand at Seymourville from the 2014 NI43- 101 technical report for Claim Post Resources.7

The acid base accounting test showed a sulphide content of 0.235% from the iron sulphide (pyrite, marcasite) in the sand. The sand also contained a small amount of CaCO3 which would act to neutralize acid formed from oxidation of the pyrite. The acid potential is expressed in terms of CaCO3.28 A net neutralization potential of -2.01 is equivalent to a net acid potential of 2.01 tonnes of sulphuric acid per 1000 tonnes of sand.

These results were submitted to the public review of the Wanipigow Sand Project.29 The proponent declared that there was no pyrite in the sand. The Approvals Branch did not act on the certified laboratory report information in the NI 43-101 technical report. It appears that the unsupported declaration of the proponent was accepted over certified lab results from a NI 43-101 technical report.12 The engineering company that prepared the Wanipigow EAP also prepared the CWS EAP.29 The presence of marcasite and pyrite in the sandstone formation was not included in either EAP.

Sand samples were collected by local residents at Vivian in the spring of 2020. The CWS extracted sand piles at Vivian had been exposed and weathered for over one year. The collected sand samples were sent for analysis by ASL laboratories. The results showed the presence of 0.02% sulphide and no CaCO3. This is consistent with all the CaCO3 consumed by neutralization of the acid produced over a year of weathering. There was still sulphide present conclusively establishing that the sand at Vivian contains pyrite. The ALS report has rounded this to one significant of 0.6 tonnes. The certified lab results also show the presence of heavy metals in the sand. The acid base accounting results and trace metal analysis of the Vivian sand is given in Figure 10.

Figure 10. Trace Metal and Acid Base accounting results by ALS Laboratories for Vivian sand.

11. Potential for Acid Formation from Pyrite and Marcasite in CWS Sand Extraction

In the Steinbach area the bicarbonate concentration in the sandstone aquifer is about 350 mg/L.25 Bicarbonate could neutralize acid produced from oxidation of pyrite. The ability of bicarbonate to neutralize acid produced from pyrite oxidation is complex. At pH 8.3, carbonate is converted to bicarbonate. At pH 4.5, it is certain that all carbonate and bicarbonate are converted to carbonic acid. Below this pH, the water is unable to neutralize the sulphuric acid.32 To determine the potential for acid neutralization from the bicarbonate in the water a titration test is required.33 Given that air is continually injected into the aquifer for up to 5 days during sand extraction the large amount of air would be expected to exceed the buffering capacity of the groundwater with respect to the acid produced from the oxidation of pyrite. The large amount of pyrite in the shale of the aquitard in the shale lenses in the sandstone, in pyritic oolite layers and in marcasite coating the sand grains would not be limiting in the formation of acid.

In the abandoned quarry on Black Island Manitoba silica sand was mined from the Winnipeg Formation since the 1920’s. Oxidation of the pyrite in the shale layer overlying the white sand can be clearly seen on the excavation faces of the abandoned quarry to this day as shown in Figure 11. Litmus paper shows the seepage from the excavation faces is acidic with a pH of about 6 as shown in Figure 12. These field results demonstrate the bicarbonate naturally occurring in the sandstone is insufficient to neutralize the acid formed from pyrite oxidation. Phipps et al. (2008) reported the bicarbonate concentration over a wide area including near Black Island ranges from 226 to 532 mg/L with a median concentration of 346 mg/L similar to the concentration in the area around Steinbach.35

Figure 11. Acid drainage from excavation faces of the Winnipeg Formation sand overlain by shale at Black Island. The picture was taken by Don Sullivan Aug. 3, 2020

Figure 12. a. and b Hematite coloured water from acid drainage from Winnipeg Formation sand and overlying shale in the abandoned quarry pit at Black Island and litmus paper test showing acidic water from pyrite dissolution at Black Island after almost 100 years of leaching. The pictures were taken by Don Sullivan Aug. 3, 2020. The pH test was witnessed by Don Sullivan.

Mr. Somji in his Sept. 11 letter to the IAAC writes

“Pyrite and Aquifer Contamination

• CWS will not, and never has, harvested sand from the Black Island Member where pyrite could exist. Figure 5 is not a complete detail of the Winnipeg Formation. The upper member is called the Carmen member and is comprised of white silica sandstone. This is the member CWS harvests sand from. The lower members containing Pyrite are the Black Island members, these are layers CWS do not harvest sand from;

• CWS does not excavate or take sand from the Black Island members so Figure 6 and claims of Acid drainage are incorrect and not relevant;

• Any comparison to Black Island is not relevant as it is an entirely different minerology;

Figure 10 CWS have extensive minerology tests conducted on the Vivian Sands which have been shared with relevant authorities. The results in Figure 10 are not representative of the sand minerology, nor can the sampling authenticity be verified;

• pH of the CWS sand was taken at 7.4 to 7.6 and comparing it to the Black Island sand is not scientifically correct;

• Figure 11a,b have nothing to do with CWS;

• Using the NI 43 101 report from another company, in another area, in another deposit has no relevancy to CWS;

Mr. Somji’s references to figures 6 (Black Island excavation faces) and figure 10 (ALS lab report) are Figure 11, and Figure 10 in this report. Mr. Somji confirms that lower in the sandstone aquifer, pyrite is found. The core logs from the well information reports obtained from Manitoba Groundwater show that the sand layer varies in thickness from 14 feet to 92 feet over the entire CWS claim area. In two wells, well 204771 at SW14-10-7E about three miles southwest of the Centre Line Road site and well 198763 at Centre Line Road the shale aquitard is 70 and 86 feet thick indicating a shale layer merged with the aquitard. The aquitard is normally between 5 and 15 feet thick as shown in Figure A1. Mr. Somji’s letter does not address the variability in white sand thickness and the universal presence of shale layers at various unpredictable depths within the sandstone aquifer and the universal presence of the shale aquitard. All of the shale contains pyrite that would react with injected air to form acid.4,5,10

Mr. Somji’s claim that ALS lab results are not representative of the sand mineralogy is not supported by evidence. The sand analyzed at ALS labs was taken from sand extracted by CWS at the Vivian site. Mr. Somji’s letter of Sept. 11 does not give results of CWS analysis of the sand. I requested in my submission to the public review of the CWS Vivian sand facility project that CWS complete an independent geochemical analysis including acid base accounting test and trace metals analysis on representative core logs of sand over the entire CWS claim area.12 This request for a complete independent geochemical analysis was ignored.

Mr. Somji’s claim that the mineralogy at Seymourville and Black Island is not representative for the CWS mining claims is not supported by evidence. The sandstone formation at Black Island was formed in the same Ordovician area and by the same processes as around Vivian.11 The papers by Phipps et al. and Schieber and Riciputi and the report by Watson all support that similar mineralogical properties of the Winnipeg Formation extend over the entire formation covering a large area from Saskatchewan to Eastern Manitoba and from Black Island in the north to Minnesota in the south8,11,35

12. Evidence for Injection into the Carbonate Aquifer of Excess Water from the Sandstone Aquifer

A resident near Centre Line Road wrote in the public comments for the Manitoba licensing approval of CWS Vivian sand processing facility; 30

“The company states that the extraction process will be a closed loop system but little details are provided. They have suggested a slurry technique but have not provided any details as to how this method was going to work. They have injected air into the aquifer previously. As I reside approximately two kilometers from the Centre Line Road, when they were extracting the sand, my water had a brown discolouration from the outdoor tap, first time in thirteen years of living in RM of Springfield. I have not seen clear documentation as to the affects on our drinking water when introducing substances into the aquifer. Common sense suggests that when you have a sealed system like and aquifer, introducing substances that are not normally present or present to that concentration will affect the natural system to some extent.”

In limestone most of the water flow is through the fractures.22 A study of limestone quarry outcrops in England by Medici et al. (2019) determines water flow velocities ranging from 500 m/day to 9000 m/day in faulted zones.The driving force for water flow was rain fall infiltration.27 The hydraulic gradient in the study by Medici et al varied from 0.005 to 0.0024 while the hydraulic gradient in the Springfield area in the carbonate aquifer is about 8.5 x 10-4.25 A CWS injection well would provide a much larger driving force that would compensate for the somewhat smaller gradient in the Springfield area compared to the Medici study.